What are the applications of fully automatic glue potting machines in the power supply industry?

The application of fully automatic glue mixing potting machines in the power supply industry is primarily focused on high-precision, high-efficiency packaging and protection. The following are their main application areas and specific scenarios:

1. Power Module Potting

● Applications: AC/DC, DC/DC power modules, inverter modules, etc.

● Functions:

Insulation Protection: Filling with epoxy resin or silicone to prevent high-voltage breakdown.

Heat Dissipation Enhancement: Thermally conductive adhesive improves heat conduction efficiency (e.g., IGBT modules).

Vibration and Moisture Resistance: For harsh environments (e.g., industrial power supplies, automotive power supplies).

Automatic two-component glue potting machine USA SEC-S3030-C

• Second Intelligent’s unique motion controller plus advanced algorithms, combined with high-precision three-axis manipulators, achieve three-dimensional high-speed and precise motion

•Through precise control of the metering motor, the two-component glue can be accurately proportioned, automatically mixed, and automatically quantitatively discharged

•With vacuum feeding and vacuum degassing, optional heating, stirring, automatic cleaning, pressure monitoring and other functions, it can cope with various complex glue environments

• The operating system is stable, the operating interface is friendly, and the cost performance is high!

2. Transformer/Inductor Encapsulation

● Applications: High-frequency transformers, inductors, and other magnetic components.

● Function:

Coil fixation: Prevents winding loosening due to vibration.

Reduces eddy current losses: Eliminates air bubbles through vacuum potting, improving electrical performance.

3. PCB Protection

● Applications: Power control boards and driver circuit boards.

● Function:

Triple-proofing (moisture-proof, dust-proof, and mildew-proof): Coating with polyurethane (PU) or silicone.

Component stress buffering: Reduces solder joint cracking caused by temperature fluctuations (e.g., LED driver power supplies).

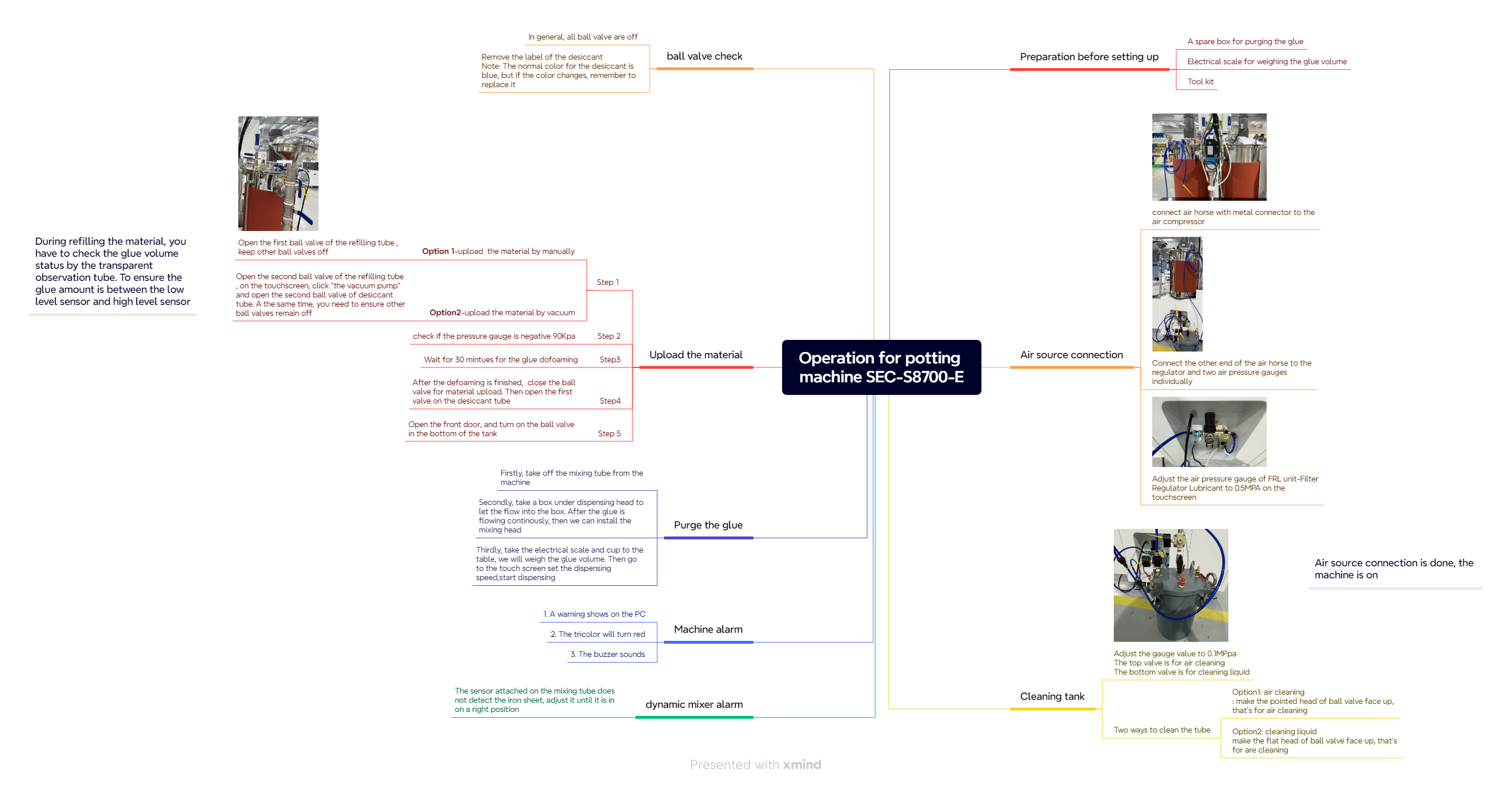

Two component glue dispensing potting machine SEC-S8700-E

Second Intelligent glue potting machine SEC-S8700-E is a two-component glue potting machine, which is compact and functional, flexible in manual operation, and Super cost-effective. The metering motor of this equipment is precisely controlled by PLC to achieve accurate proportioning, automatic mixing, and automatic quantitative dispensing of two-component glue. It has functions such as vacuum feeding, vacuum degassing, heating, stirring, and automatic cleaning, and can cope with various complex gluing environments; it adopts a unique industrial design, with a generous appearance, compact structure, stable operating system, friendly operating interface, and high cost-effective.

4.Capacitor/Terminal Potting

Applications: Electrolytic capacitors, filter capacitors, and terminal blocks.

Function:

Leakage prevention: Fills gaps in high-voltage capacitors.

Mechanical reinforcement: Prevents terminal loosening (e.g., charging station power supply terminals).

5.New Energy Power Supply Equipment

●Application Scenarios:

Charging Pile: Charging Module Potting (requires flame-retardant adhesive, such as UL94 V-0).

Energy Storage Battery: BMS Management System PCB Potting.

Photovoltaic Inverter: Anti-PID (Potential Induced Degradation) Potting.

6.Special Power Supply Applications

Medical Power Supply: Potting adhesive must meet biocompatibility (such as ISO 10993 standards).

Military Power Supply: Potting must pass high and low temperature (-40°C to 125°C) and salt spray tests.

Advantages of Fully Automatic Glue Potting Machines

High Precision: A metering pump controls the mixing ratio (e.g., 1:1, 2:1) with an error of ≤1%.

Automation: Combined with a vision system or robotic arm, it enables assembly line operations (e.g., automotive power supply production lines).

Fast Curing: Supports UV adhesives and low-temperature curing adhesives (80°C/10 minutes).

Complex Processes: Capable of handling requirements such as underfill and dam-and-fill.

Typical glue types

Glue type | characteristic | Applicable scenarios |

Epoxy resin | High hardness and high temperature resistance | Power module potting |

Organic Silicone | Good elasticity and aging resistance | Car power supply |

Polyurethane | Wear-resistant and low cost | Consumer Power Supplies |

Thermally conductive | Thermal conductivity 1~5 | High power power supply |

adhesive | W/mK | cooling |

In short, the fluid dispensing machine is one of the core equipment in semiconductor packaging and advanced processes, and its technological upgrade directly promotes the performance improvement and miniaturization of semiconductor components.

Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component potting machines and coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.