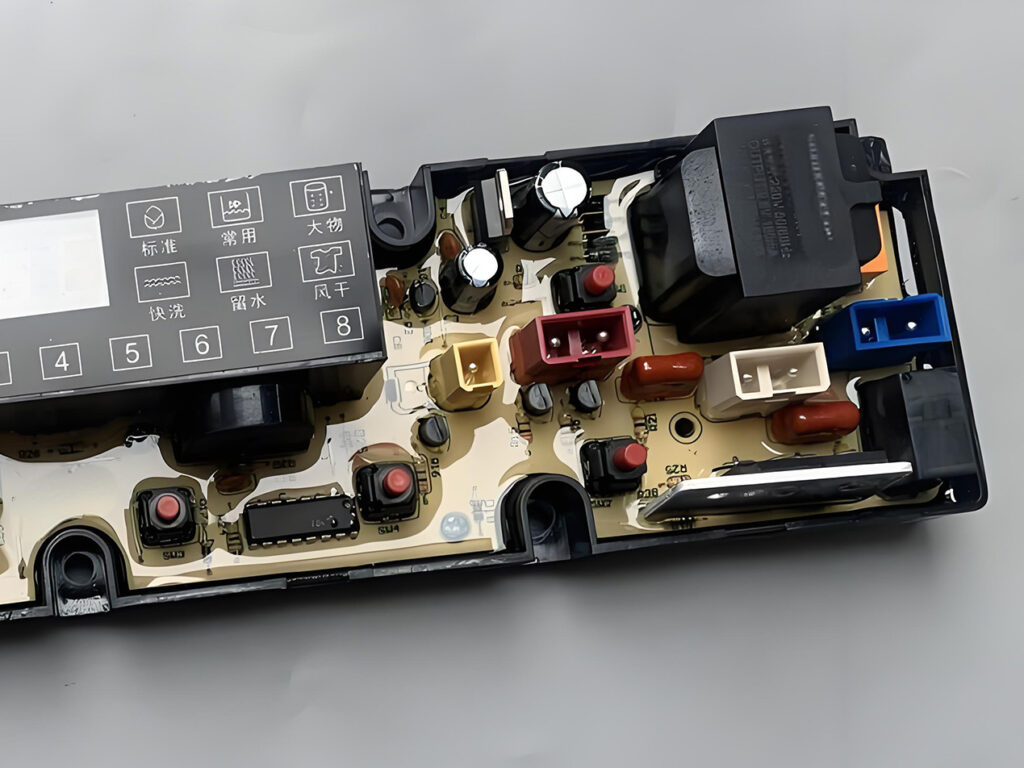

The encapsulation of washing machine control boards (computer boards) is one of the most typical applications of automated potting machine, directly impacting the reliability, safety, and lifespan of the washing machine.

Below, I will elaborate on the application of Automatic Glue Potting Machine in the encapsulation of washing machine control boards from the perspectives of “why encapsulation is needed,” “what adhesive to use,” “how to perform encapsulation,” and “the benefits of encapsulation.”

Ι.Why is potting necessary for washing machine control boards? (Necessity) Washing machines operate in extremely harsh environments, posing multiple threats to the control board:

1.Water and moisture protection: The internal humidity of washing machines is extremely high, especially in top-loading washing machines. Condensation and accidental splashes can cause short circuits and component corrosion.

2.Corrosion protection: Detergents, fabric softeners, bleach, and other chemicals are corrosive; their vapors can corrode circuit boards and component leads.

3.Shock and loosening prevention: Washing machines generate severe vibrations during the spin-drying process. Prolonged vibration can lead to solder joint cracking and component loosening.

4.Heat dissipation and insulation:Power devices on the control board (such as SCRs) generate heat during operation. Potting compound helps dissipate heat and provides excellent electrical insulation, preventing high-voltage creepage.

5.Dust and insect protection:Sealing prevents dust, cockroaches, and other foreign objects from entering and causing malfunctions.

Potting provides a “solid protective chamber” for the precision electronic control board, completely isolating it from the harsh environment.

Vacuum potting technology

Inline vacuum potting machine: For example, the SEC-S400-ZL/ZHL ensures no air bubbles remain in the adhesive during potting through rapid vacuum extraction and high sealing performance, reducing leakage caused by bubbles.

Ⅱ.Commonly Used Potting Compounds

The main potting compounds used are two-component silicone potting compounds and epoxy resin potting compounds, each with its own strengths:

a.Two-component silicone potting compounds

● Main advantages: Good elasticity, resistance to high and low temperature impacts (-50℃~200℃), excellent vibration resistance, and repairability (the compound is soft and can be dug open for repair).

● Main disadvantages: Relatively weak adhesion, higher cost.

● Applicable scenarios: Mainstream choice. Especially suitable for environments with high vibration and large temperature differences, where ease of maintenance is required.

b.Epoxy Resin Potting Compound

● Main Advantages: High hardness, strong adhesion, superior chemical resistance, good moisture resistance and sealing, and generally lower cost.

● Main Disadvantages: High hardness and brittleness, poor resistance to thermal shock, and difficult repair (requires chiseling).

● Applicable Scenarios: Situations requiring strict control of hardness, adhesion, and cost, and where the operating environment has minimal temperature differences.

Current Trend: In the washing machine control board field, two-component silicone potting compounds have become the absolute mainstream choice due to their excellent weather resistance and repairability.

Automatic In-Line Vacuum Glue Potting Machines Production Line

Application Proces:

Loading station→ Transfer machine→ Preheating oven→ Visual potting machine→ Curing Oven→ Unloading station

III. Application Process and Key Technologies of Potting Machines Using dispensing machines for potting represents a leap from manual mixing to automated, precise operation.

1.Process Flow:

● Pre-treatment: After the control board completes component insertion, wave soldering/reflow soldering, and testing, it enters the dispensing station.

● Fixing and Preheating: The control board is fixed in a fixture (tray). Sometimes, the board is preheated (e.g., to 60℃) to reduce adhesive viscosity, remove air bubbles, and improve flowability.

● Automatic Potting:

*Mixing and Proportioning:* The dispensing machine precisely measures component A (silicone) and component B (curing agent), achieving uniform mixing through a static mixing tube or dynamic stirring head.

*Trajectory Dispensing:* The program is written into the dispensing machine’s control system. The machine drives the dispensing valve along a preset path, ensuring that the adhesive evenly covers all critical areas (such as chips, high-voltage areas, and connector peripheries), while avoiding dispensing into unwanted areas (such as the inside of sockets or the surface of heat sinks).

*Quantitative Control:* Precisely controlling the amount of adhesive used on each board ensures consistency and avoids waste.

● Curing:After potting, the boards are conveyed to the curing line for curing at room temperature or under heated conditions. Silicone typically surface-dries within a few hours and fully cures in 24-72 hours.

Post-Inspection and Testing: After curing, the appearance of the potting is inspected, and electrical safety and functional tests are performed.

2.Key Advantages of Dispensing Machines in This Application:

● High-Precision Mixing:Ensures precise mixing of two-component adhesives (e.g., 10:1), which is crucial for guaranteeing the final performance of the adhesive (cured strength, hardness, electrical properties).

● Bubble-Free Operation: Advanced vacuum degassing systems or metering pump technology significantly reduce air bubbles in the adhesive, preventing these areas from becoming weak points in the coating.

● Consistency and Efficiency: Completely eliminates the randomness of manual dispensing, ensuring consistent product quality. The speed is far faster than manual dispensing, meeting production line cycle times.

Complex Track Capability: Easily achieves three-dimensional routing, precisely wrapping uneven boards (containing heat sinks, large capacitors, etc.).

● Adhesive Savings: Precise metering reduces waste, significantly lowering material costs in the long run.

Ⅳ.Summary of Application Benefits

For manufacturers, introducing a dispensing machine to the washing machine control board production line brings systemic improvements:

Improved Quality and Reliability: Significantly reduces control board failure rates caused by moisture, corrosion, and vibration, enhancing product reputation and brand image.

Improved Production Efficiency: Automated assembly line operation ensures stable and controllable production cycles.

Reduced Overall Costs: Reduces rework rates, after-sales maintenance costs, and warranty claims. Increased glue utilization reduces waste.

Standardized Processes: Enables digital and parameterized production, facilitating quality traceability and management.

Safety and Environmental Protection: The closed system reduces glue contact and evaporation, improving the workshop environment.

Ⅴ.Typical Industry Practices

Almost all mainstream washing machine brands (such as Haier, Midea, Siemens, LG, Panasonic, etc.) have adopted automated two-component silicone dispensing production lines in their control board production. This has become the standard process for high-end, reliable washing machines.

Dispensing Challenges and Countermeasures:

● Connector Sealing: Requires precise control of the glue amount, ensuring a seal at the base without flowing into the pin holes. Commonly used methods include pre-sealing with adhesive dispensing or using custom-designed fixtures for masking.

● Heatsink Treatment: Heatsinks for power devices typically do not require potting; the dispensing machine automatically skips this step or a masking fixture is used.

● Bubble Removal: In addition to equipment debubbling, preheating the board and using low-viscosity adhesives also help remove bubbles.

Conclusion:

In the potting application of washing machine control boards, the potting machine is the core equipment for achieving efficient, reliable, and large-scale production. By combining with high-performance two-component silicone potting compounds, it provides a robust and reliable “brain shield” for modern washing machines, and is one of the key technological links in the home appliance industry to improve product quality and durability.

Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component potting machines and coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.