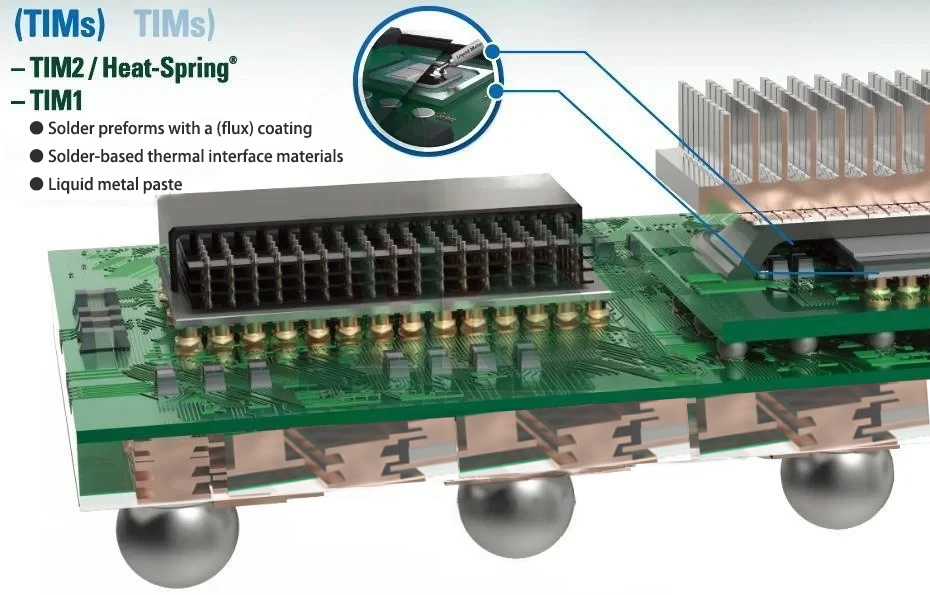

Thermal Interface Materials (TIM) for Electronics/Electric Vehicle Dispensing Applications?

Thermal interface materials are key materials for solving the heat dissipation bottleneck of modern electronic devices. Dispensing technology has become the mainstream process for TIM applications due to its high automation, high flexibility and suitability for complex shapes, especially in high-power, high-value fields such as electric vehicles.

Ι.Core Concept: Why Are TIM and Dispensing Processes Critical for Electric Vehicles?

1.The Extreme Importance of Thermal Management: Core components of electric vehicles (such as battery packs, electric drive systems, onboard chargers, power electronics, etc.) generate significant heat during operation. Overheating directly leads to performance degradation, reduced lifespan, and even safety incidents. Efficient thermal management is the cornerstone for ensuring vehicle power, safety, and reliability.

2.Role of TIM: Between two seemingly flat solid surfaces (e.g., chip and heat sink), numerous microscopic voids filled with poorly conductive air actually exist. TIM fills these gaps, displacing air to establish an efficient thermal conduction pathway.

3.Advantages of Dispensing Process:

● Automation and Efficiency: Suited for large-scale automated production, ensuring consistency and high cycle rates.

● High Material Utilization: Precisely controls dispensing volume to minimize waste, particularly for expensive thermal greases.

● Adaptability to Complex Structures: Easily achieves various coating patterns like L-shapes, grids, and circles, ensuring perfect coverage on irregular surfaces.

● Reduced Air Bubbles: Advanced dispensing equipment and techniques effectively minimize bubbles, enhancing thermal performance.

Ⅱ.Typical Application Cases

The following are examples of TIM dispensing applications in several key components of electric vehicles.

Case 1: Battery Pack Thermal Management

● Application Scenario: In a battery module, heat generated by the battery cells needs to be removed via a cooling plate (usually a liquid cooling plate). The TIM is placed between the bottom/side of the battery cell and the cooling plate.

● TIM Material Selection:

Thermal Conductive Gel: This is currently the most popular choice. It offers good thermal conductivity (1.0-5.0 W/mK), excellent conformability (allowing for wide tolerances), low stress, and can be automated through the dispensing process.

Thermal Conductive Pads: These can also be used, but are typically applied via preforms. Dispensing gel offers advantages in terms of coverage and automation.

● Dispensing Process:

Pattern: Typically, one or more “dots” or a “square”-shaped bead of adhesive is applied to each battery cell location on the cooling plate.

Challenge: The amount of adhesive must be precisely controlled to ensure that after the battery cells are pressed together, the TIM fully covers the interface and does not overflow due to excessive compression, potentially contaminating the battery cells or other components.

Case Value: Through efficient glue dispensing machine of TIM, the battery pack maintains efficient heat dissipation during fast charging and high-rate discharge, maintaining the battery cells within the optimal operating temperature range and significantly improving battery life and safety.

Case 2: Electric Drive System (Inverter, Motor Controller)

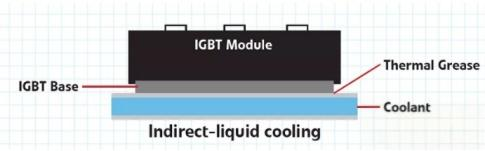

● Application Scenario: The core heat-generating components in the inverter are IGBTs or SiC power modules. The heat generated by these modules needs to be transferred to the liquid cooling jacket via a heat sink substrate.

Thermal Conductive Gel: This is currently the most popular choice. It offers good thermal conductivity (1.0-5.0 W/mK), excellent conformability (allowing for wide tolerances), low stress, and can be automated through the dispensing process.

Thermal Conductive Pads: These can also be used, but are typically applied via preforms. Dispensing gel offers advantages in terms of coverage and automation.

● Dispensing Process:

Pattern: Typically, one or more “dots” or a “square”-shaped bead of adhesive is applied to each battery cell location on the cooling plate.

Challenge: The amount of adhesive must be precisely controlled to ensure that after the battery cells are pressed together, the TIM fully covers the interface and does not overflow due to excessive compression, potentially contaminating the battery cells or other components.

Case Value: Through efficient dispensing of TIM, the battery pack maintains efficient heat dissipation during fast charging and high-rate discharge, maintaining the battery cells within the optimal operating temperature range and significantly improving battery life and safety.

Case 2: Electric Drive System (Inverter, Motor Controller)

● Application Scenario: The core heat-generating components in the inverter are IGBTs or SiC power modules. The heat generated by these modules needs to be transferred to the liquid cooling jacket via a heat sink substrate.

Automatic In-line PCB Glue Dispensing Machine SEC-DH400L

Second Intelligent In-line Automated Glue Dispensing Machine SEC-DH400L adopts an integrated mineral casting design, with ultra-high precision and super stability, powerful expansion capabilities, and can realize ion cleaning, dispensing, detection, UV exposure and other functions;

Adopting a gantry structure, it can bear large loads, stable structure, and a powerful CCD visual positioning system, which can meet the requirements of Mark point positioning, edge positioning, and 3D scanning positioning; strong scalability, and can expand AOI detection 3D detection, UV exposure curing and other functions;

Strong platform compatibility, contact and non-contact dispensing, single-head and multi-head synchronous dispensing, automatic compensation and adjustment of double-head spacing, five-axis dispensing function based on needle A/R displacement, etc.

● TIM Material Selection:

High-thermal-conductivity insulating silicone grease: This is a traditional and widely used choice, with a thermal conductivity of 3.0-6.0 W/mK or even higher. It requires dispensing.

Phase-change material: It is solid at room temperature, making it easy to install. At operating temperatures (e.g., 50-60°C), it softens into a paste, effectively filling the interface. It can be applied via dispensing or preformed sheets.

Thermal conductive gel: Also applicable, especially in applications requiring tight tolerance compensation.

● Dispensing Process:

Pattern: Typically, an “X” or “grid” pattern is applied to the backside of the power module to ensure uniform coverage and an optimal heat conduction path.

Challenges: Extremely high cleanliness requirements are required; any dust or air bubbles can cause hot spots, impacting IGBT lifespan. Dispensing accuracy and stability are crucial.

Value of this application: Ensures that heat generated by high-power semiconductors is quickly dissipated, ensuring the electric drive system maintains maximum power output and improving vehicle energy efficiency and reliability.

Case 3: On-Board Chargers and DC-DC Converters

● Application Scenario: These power electronics contain numerous magnetic components (transformers, inductors) and switching transistors (MOSFETs), all of which require heat dissipation.

● TIM Material Selection:

Thermal adhesive/thermal conductive glue: In addition to conducting heat, it also provides structural bonding. It is often used to directly bond heat-generating components (such as inductors) to metal casings for heat dissipation.

Thermal gel/silicone grease: Used between chips and heat sinks.

● Dispensing Process:

Precise dispensing is performed based on component shape and position. For bonding applications, the width and height of the glue line must be controlled to ensure sufficient bond strength and thermal conductivity.

SMT automatic glue dispenser SEC-DH600L

Second Intelligent high precision smt automatic glue dispenser machine apply epoxy resin to the bottom of the PCB board for underfill

Second Intelligent smt automatic glue dispenser automation SEC-DH600L has the following advantages:

● CCD visual programming precise positioning, visual correction, improve programming efficiency and dispensing accuracy;

● Chinese and English operating system, the software interface layout is clear, the operation is simple, easy to learn and understand;

● Support visual inspection, integrated control of dispensing and visual inspection, multi-purpose machine, effective control of dispensing yield;

● It can be equipped with a lin e laser scanner for 3D path guidance and flexible dispensing;

● The software can support a variety of dispensing systems and functional module applications, such as automatic needle alignment, automatic

height measurement, dispensing weighing compensation, five-axis linkage and other functions, which can effectively overcome the difficulties of

various dispensing processes and help improve quality;

Ⅲ.Key Considerations for the Dispensing Process

Achieving a successful TIM application requires more than just material selection; the dispensing process itself is equally important:

1.Dispensing Equipment:A high-precision, high-stability screw pump or jet valve is required to handle TIM materials of varying viscosities and ensure consistent dispensing volume.

2.Material Rheology: The viscosity, thixotropy, and other rheological properties of TIMs directly impact dispensing performance. Too thin will cause runny dispensing, while too thick will be difficult to dispense and prone to stringing.

3.Automation and Vision Systems: These are typically integrated into automated production lines, coordinated with robotic or gantry motion, and use vision systems for positioning and adhesive path quality inspection.

4.Curing Process: Some TIMs (such as thermally conductive adhesives) require heat curing, and the production line cycle time must be aligned with the curing time.

Ⅳ.Development Trends

Higher Thermal Conductivity: With increasing power density, the thermal conductivity requirements for TIMs are becoming increasingly stringent.

Lower Thermal Resistance: Focus is placed not only on the thermal conductivity of the material itself, but also on the contact thermal resistance of the entire interface.

Automation and Intelligence: The dispensing machine process is integrating more sensors (such as pressure and vision) to enable real-time monitoring and closed-loop control, ensuring dispensing quality for every product.

New Material Applications: The application of new thermally conductive materials such as carbon nanotubes and graphene is being explored and is expected to bring breakthrough performance improvements.

Summary

In the electric vehicle industry, the dispensing of thermal interface materials (TIMs) is a multidisciplinary technology involving materials science, precision mechanics, and automated control. It addresses macroscopic heat dissipation challenges at the micro level and plays a key role in ensuring the power, safety, and longevity of electric vehicles. From battery packs to electric drive systems, efficient, reliable, and automated TIM dispensing solutions have become an indispensable component of intelligent electric vehicle manufacturing.

Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component potting machines and automatic coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.