Application of the SEC-3030-C two component potting machine in Doming Labeling Process

Lubricating Grease dispensing technology is widely and critically used in the automotive industry for bearings and gears. It enables precise, efficient, and clean grease application, making it an indispensable part of modern automated automotive production lines.

Below are several specific application examples and detailed explanations:

Ι.Bearing Application Cases Various bearings are widely used in automobiles.

The amount, location, and consistency of grease application directly affect the bearing’s lifespan, noise level, and performance.

Crystal Resin Doming Label Process

The doming label is believed to be familiar to many printing and design decoration companies. Following the completion of signage and other printed materials, a layer of high-tensile coating is typically applied and cured onto their surfaces. Its appearance is crystal-clear, presenting a protective layer with a convex, arched surface. This process imparts a full, transparent, crystal-like texture to the product, resulting in a three-dimensional, translucent finish that sparkles like crystal. It is commonly referred to as the crystal dome process. It is further distinguished by its colloidal drip-casting technology. Signs produced using this method are termed crystal drip-glazed nameplates.

Printing & Design & Packaging Decoration Industry

The application of two component potting machine in label stickers is primarily evident within the handicraft sector. They are employed for high-precision potting in products such as stickers, nameplates, labels, badges, panels, decals, signage, automotive panels, metal, glass, insignia, buckles, solar panels, and LED product encapsulation. This addresses issues like adhesive overflow and air bubbles, thereby enhancing product yield and aesthetic appeal.

● Packaging & Gift Industry

Crystal resin labels are extensively used for corporate logos, water bottle graphics, and similar products. Crystal resin can be poured onto materials such as brushed silver, brushed gold, transparent substrates, PPT, PVC, and paper-based materials. After screen printing or silk-screen printing, these substrates are coated with crystal resin to achieve a distinctive effect. The dispensing machine utilises two-component adhesives to create highly transparent, three-dimensional decorative finishes, enhancing product aesthetics and market competitiveness.

● Craft Industry Applications and Metal fittings

In craft production, crystal resin can be poured over various ornaments and decorative pieces to impart a crystalline, translucent appearance, elevating both aesthetic appeal and product value. Badges, buttons, and similar crafts may undergo surface treatment using rigid crystal resin.

Crystal resin is equally suitable for metal signage, including stainless steel mesh plates, aluminium plates, and CD-textured plates. Furthermore, after surface treatments like nickel plating, stamping, or etching logos, metal surfaces can be coated with crystal resin to enhance both decorative appeal and durability. The resin dispensing machine ensures uniform adhesive application, followed by grinding and polishing to achieve a high-gloss finish.

Commonly Used Label Adhesives

Crystal glue is usually polyurethane PU glue, epoxy resin AB glue, and some may also be UV adhesive.

Epoxy AB adhesive: Easy to operate, low price but prone to yellowing

Polyurethane PU adhesive: It can achieve UV resistance and remain yellow for three years, with strong weather resistance but sensitivity to moisture, suitable for outdoor products such as vehicle signs. This two-component AB adhesive combines various high-quality ingredients such as epoxy resin, benzyl alcohol, and polyetheramine. It not only has low viscosity and high transparency, but also has excellent resistance to yellowing and bending. As a result, it exhibits high fullness and transparency.

UV Instant adhesive: Single component UV curable adhesive, UV drying in 5-30 seconds, with a light transmittance of over 90% after curing, suitable for crystal image production (PK-5975) and precision craft repair

The crystal glue on the market is roughly divided into: flat soft glue, flat hard glue, curved soft glue, curved hard glue, injection glue, craft fake water, polishing glue, etc. The use of crystal glue can not only protect the surface of handicrafts and jewelry, but also increase the glossiness and brightness of the product surface.

Pain points of handmade craftsmanship

● When preparing glue, it is necessary to strictly follow the weight ratio. If the proportion of adhesive A is too high, it will lead to a decrease in the hardness of the adhesive, an extension of the curing time, and even the occurrence of non drying; If the proportion of B glue is too high, it will increase the hardness of the glue and may also cause problems such as non drying or poor adhesion. During the mixing process, it is essential to ensure that the adhesive A and B adhering to the container wall are thoroughly mixed together. If the mixing is not uniform, it may cause the glue to not dry or have a hard texture.

(2) Unable to produce in large quantities, seriously affecting efficiency

(3) Unable to completely vacuum defoam

The dual liquid glue filling machine has functions such as stirring, precise mixing ratio, and vacuum defoaming, which can completely solve this process problem and achieve fully automated mass production

Our Company Customer Case

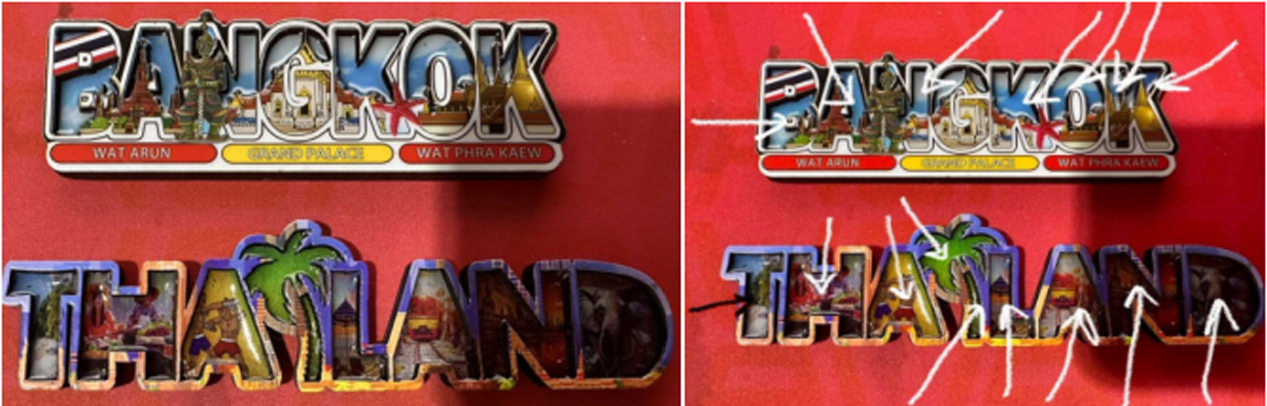

Client 1 : Artistic Souvenirs from Tourism Authority of Thailand

Usage: Used to make souvenirs for government gifts or tourist attractions

Adhesive: AB two-component crystal adhesive, mixing ratio 2:1

Solution: SEC-S3030-C two component machine (gear pump+dual liquid dynamic valve)

Technical advantages:

It has application characteristics such as precise gluing and efficient operation.

● Precise control: It can accurately control the amount and speed of crystal glue injection based on preset parameters, ensuring the stability and consistency of the injection quality. Using micro injection technology, the error in glue amount can be controlled at the micrometer level, reducing glue overflow and material waste.

● Capable of handling complex glue dispensing operations: It can replace manual dispensing operations for high-precision and rapid marking and line drawing on various flat or curved products, and has the characteristics of high dispensing quantitative accuracy and good repeatability.

(3)High quality rate: Through automated positioning, high-precision mixing, and vacuum bubble elimination, the product qualification rate has been increased by over 95%.

Client 2: A design and printing company from a Central Asian country

Usage: Used to make outdoor labels and signs of different styles, with label sizes ranging from 10 × 10 millimeters to 500 × 700 millimeters; Production capacity of 4000-10000 Pcs/day

Adhesive: two-component epoxy resin with a mixing ratio of 97:100

Solution: SEC-S3030-C (gear pump+dual fluid dynamic valve)

Technical advantages:

SEC-S3030-C can seal and glue signs made of metal, plastic, and other materials to enhance waterproofing and durability. Through automated precise proportioning and defoaming treatment, it can be finely adjusted after dripping to ensure a natural leveling of 2mm thickness, ensuring a smooth and flawless finished product. It is also waterproof, moisture-proof, and does not change color for many years outdoors.

Large scale production of labels with different shapes: SEC-S3030-C can achieve automated operation, greatly improving production efficiency. Selective visual positioning system, programmed with programming software, can replace manual labor in mass production of different shape labels on various flat or curved products, greatly liberating productivity.

Precise control: It can accurately control the amount and speed of crystal glue injection based on preset parameters and pump usage and selection, ensuring the stability and consistency of injection quality, avoiding overflow and bubbles, ensuring high transparency and three-dimensional effect, suitable for products such as labels and tags.

#Doming Label# #label stickers# #two component potting machine# #Doming Labeling# #Epoxyadhesive# #Polyurethane adhesive# #AB component potting machine# #crystal adhesive#

[contact-form-7 id=”5″ title=”Contact form 1″]