Precision and Efficiency in Tackling Adhesive Potting Stringing and Leakage, Empowering the Future of Smart Manufacturing

In modern industrial manufacturing, the application of potting technology is becoming increasingly widespread. However, as production demands increase, issues such as adhesive stringing and leakage during the potting process have gradually become critical factors affecting product quality and production efficiency. Shenzhen Second Intelligent Equipment Co., Ltd. (hereinafter referred to as “Scond Intelligent”), as a leading provider of smart equipment solutions in the industry, not only continues to innovate in efficient and precise potting technology but also offers a series of advanced solutions to address adhesive stringing and leakage, helping enterprises overcome technical challenges, improve production efficiency, and enhance product quality.

Adhesive stringing and leakage phenomena are typically caused by the following factors:

1.High viscosity of adhesives: High-viscosity adhesives tend to form strings during potting, preventing uniform distribution.

2.Improper pressure control: Excessive or unstable potting pressure can lead to adhesive overflow or leakage.

3.Incomplete mixing: Inadequate mixing of two-component adhesives can result in poor curing or localized leakage.

4.Equipment design flaws: The design of the potting equipment’s nozzle and the stability of the adhesive supply system directly affect the fluidity and uniformity of the adhesive.

These issues not only reduce production efficiency but can also lead to decreased product performance, aesthetic defects, and even shortened product lifespan.

Second Intelligent provides a series of innovative equipment and technical solutions to address adhesive stringing and leakage:

1.High-precision metering and mixing technology

● Two-component dynamic mixing valve: By using pull-back switching and dynamic mixing technology, it ensures uniform mixing of adhesives during potting, avoiding leakage caused by incomplete mixing.

● Screw pump adhesive supply system: With stable adhesive supply performance, it is suitable for high-viscosity and highly filled materials, reducing stringing caused by viscosity differences.

2. Smart control systems

● PLC control system: For example, the SEC-S8700-E two-component potting machine ensures uniform adhesive distribution and reduces stringing and leakage through high-precision metering and automatic mixing.

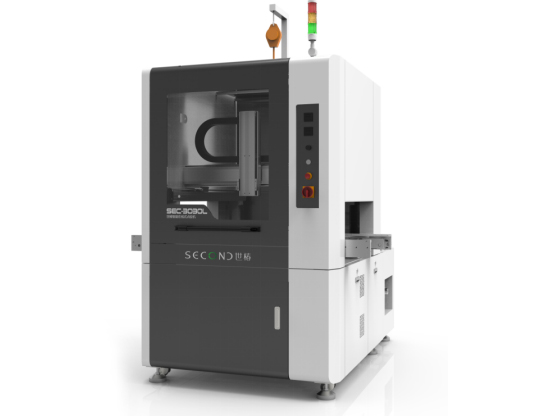

● Servo motor and high-precision motion platform: For example, the SEC-S3030-L/LH fully automatic inline potting machine ensures precise alignment of the nozzle with the product surface through precise three-dimensional motion control, preventing adhesive overflow.

3.Vacuum potting technology

Inline vacuum potting machine: For example, the SEC-S400-ZL/ZHL ensures no air bubbles remain in the adhesive during potting through rapid vacuum extraction and high sealing performance, reducing leakage caused by bubbles.

4.Smart production line integration

Vacuum potting production line: By integrating MES systems for data collection and uploading, it covers key data such as production quantities and equipment exceptions, enabling real-time monitoring of the potting process and timely resolution of stringing and leakage issues.

Second Intelligent’s glue potting equipment and technology have performed exceptionally well in multiple fields, particularly in addressing stringing and leakage issues, achieving significant results:

● Automotive manufacturing: In the potting of automotive electronic modules, Second Intelligent’s equipment ensures uniform adhesive distribution through high-precision metering and dynamic mixing technology, preventing performance degradation caused by stringing and leakage.

● Electronic components: In the two components dispensing machine of PCB boards, the SEC-S8700-E equipment ensures no stringing through precise metering and mixing functions, enhancing product reliability.

● New energy sector: In the potting of battery modules, Second Intelligent’s vacuum potting technology effectively resolves issues of bubbles and leakage, improving battery safety and lifespan.

Second Intelligent , Your Smart Equipment Partner.

Shenzhen Second Intelligent Equipment Co., Ltd., established in 2006, is a high-tech enterprise specializing in the research, production, and sales of fluid control and smart equipment. The company boasts a strong R&D team and a comprehensive after-sales service system, with products exported to numerous countries and regions worldwide.

Second Intelligent consistently prioritizes technological innovation as its core strategy and customer needs as its guiding principle. It is committed to providing efficient, intelligent, and reliable equipment solutions. Whether you require standalone equipment or fully automated production lines, Second Intelligent can offer customized solutions tailored to your needs, helping enterprises achieve smart manufacturing upgrades.

Choose Second Intelligent, choose quality and the future!