- HOME

- MACHINES

-

APPLICATIONS

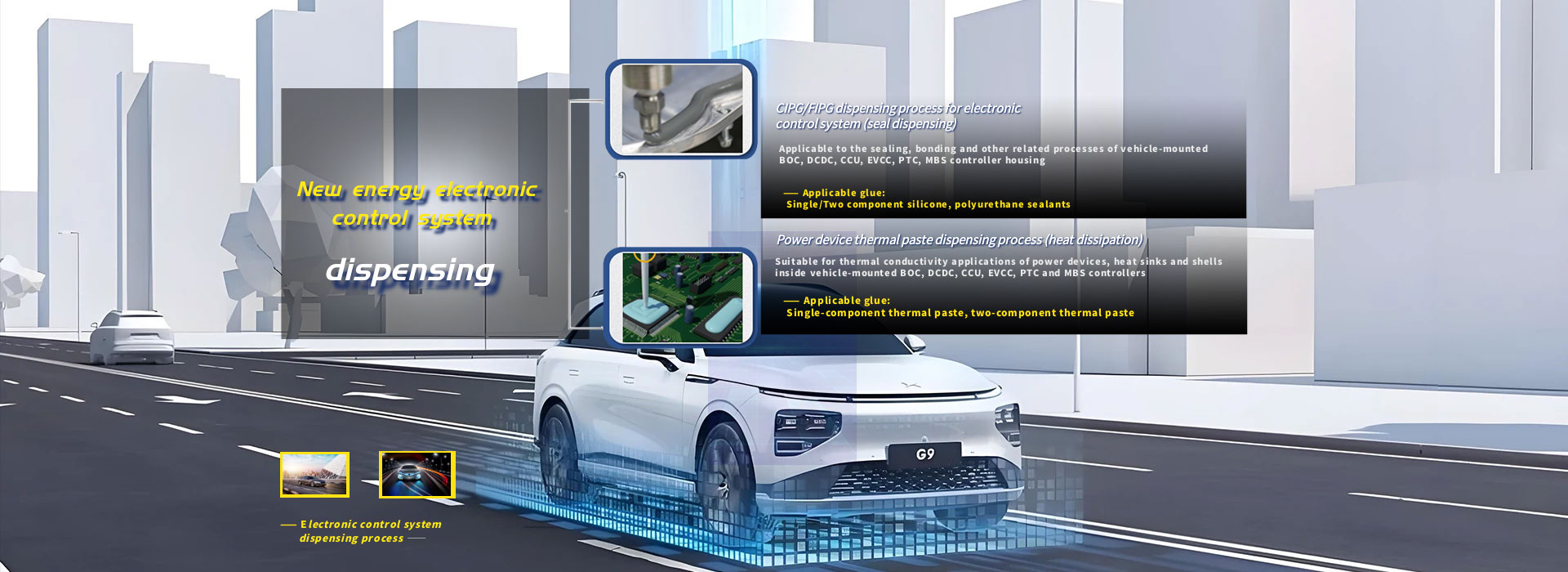

- Automotive Electronics Dispensing Solutions

- Overall solution for lithium battery equipment

- Consumer electronics industry equipment solutions

- AR equipment overall solutions

- IGBT Industry Equipment Solutions

- Power supply industry equipment solutions

- Vacuum injection industry solutions

- Hydrogen power intelligent equipment solutions

- LED Light Dispensing Solutions

- Home Appliance Industry Solutions

- SMT & PCB Assembly Dispensing Solutions

- Semiconductor Components Dispensing

- ACCESSORIES

- NEWS

- ABOUT US

- CONTACT US

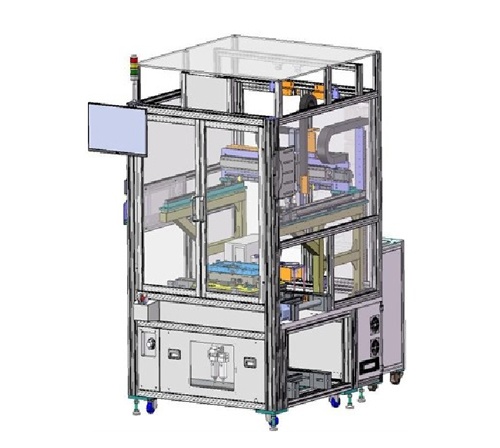

Automatic CIPG-FIPG thermal paste dispensing machine

SEC-DH651

Feature :

Customized appearance can be consistent with the style and appearance of the new energy industry production line

Online fully automatic operation mode saves manpower and improves efficiency

Rich functions, standard needle correction, glue quantity inspection, visual positioning, product deformation correction, product information scanning and other functions.

Powerful expansion capabilities, expandable plasma cleaning, 3D detection, etc.

Stable and efficient vacuum glue supply system reduces glue bubbles and eliminates glue waste

Advantage :

- The control software is easy to operate and program;It has the functions of drawing points, lines, surfaces, arcs, circles, irregular curves, continuous interpolation and three-axis linkage;

- Powerful PC compatibility, with Logoshop software, can import various file formats (such as .NC, .AI, .DXF, .JPG, .BMP, scanners, etc.) generated by mainstream design software (such as Jingdiao, AutoCAD, CoralDraw, etc.)

- Equipped with 130W pixel CCD visual software, it has a correction function, and the product can be automatically corrected if it has a certain range of offset;

- The equipment is equipped with laser height measurement to solve the problem of product deformation and dispensing The equipment is equipped with a low liquid level alarm function to remind the operator to change the glue in time

- The equipment is equipped with an automatic needle alignment function to avoid poor dispensing after changing the needle

- The equipment is equipped with a low air pressure alarm All doors of the equipment are equipped with safety door locks

- The equipment can be adapted to visual positioning, product deformation correction, low-temperature plasma cleaning, automatic dispensing, dispensing effect detection, automatic glue quantity inspection, RFID station passing, automatic needle correction, MES system and other rich functions

Application process :

Visual positioning + laser height measurement + syringe dispensing

Related content :

*Pre-sales services:

Providing solution consulting based on customers’ needs

Free sample test

Factory audit

Customized solutions according to customers’ needs

*Services during sale:

Production visualization

Machine quality controlling

Finished Machine test report

Logistics support upon customers’ requirement

*After-sales service:

Instruction manuals, step-by-step guides for installation and usage, and free remote video technical support

On-site technical service in 24 hours

Generally, we pack our goods with proper wooden box. However, if client has special requirment, we can customize.

Depends on terms and conditions, negotiable.

EXW, FOB,CIF…

Yes, we can produce according to the tested result. We can also product base on your design.

Yes, we will test 100% before delivery.

We keep good quality and competitive price to ensure our customers benefit. We respect every customer as our friend and we sincerely do business and make friends with them

Dispensing machine is an automatic machine and equipment that specializes in controlling fluid and dripping, coating, and potting the liquid on the surface of the product or inside the product. The glue dispenser is mainly used for glue and paint in the product process.

Glue dispensers are generally suitable for small products or electronic components, which are more precise; the products of potting dispensers are generally larger.

As long as it is a fluid with a viscosity within a certain range, it can be operated. The glue generally used in the dispenser includes red glue, hot melt glue, silica gel, grease and so on.

Equipment Features

The platform and X/Y module base are cast in mineral form, and the key surface is grinded to ensure higher accuracy and stability

Gantry type structure, bearing large load, stable structure

Powerful visual positioning system, can meet the Mark point positioning, grab edge positioning, 3D scanning positioning,

Strong scalability, can expand AOI detection 3D detection, UV exposure curing and other functions

Strong platform compatibility, contact and non-contact dispensing, to meet the dispensing operations of different products and processes

Replaceable stainless steel housing to achieve 100 levels of cleanliness

Equipment Features

The platform and X/Y module base are cast in mineral form, and the key surface is grinded to ensure higher accuracy and stability

Gantry type structure, bearing large load, stable structure

Powerful visual positioning system, can meet the Mark point positioning, grab edge positioning, 3D scanning positioning,

Strong scalability, can expand AOI detection 3D detection, UV exposure curing and other functions

Strong platform compatibility, contact and non-contact dispensing, to meet the dispensing operations of different products and processes

Replaceable stainless steel housing to achieve 100 levels of cleanliness

Equipment Features

▪ Square welding frame + sheet metal shell, integrated steel plate on the table, all mounting surfaces are precision processed to ensure accuracy and better stability

▪ Cantilever structure is suitable for products with higher aspect ratio, which can better ensure the accuracy and stability of the robot arm while meeting the large stroke

▪ Powerful visual positioning system, which can meet the requirements of Mark positioning, edge positioning, 3D scanning positioning

▪ Strong scalability, can expand AOI detection 3D detection, UV Ricoh curing and other functions

▪ Strong platform compatibility, contact and non-contact dispensing, to meet the dispensing operations of different products and processes