Introduction:

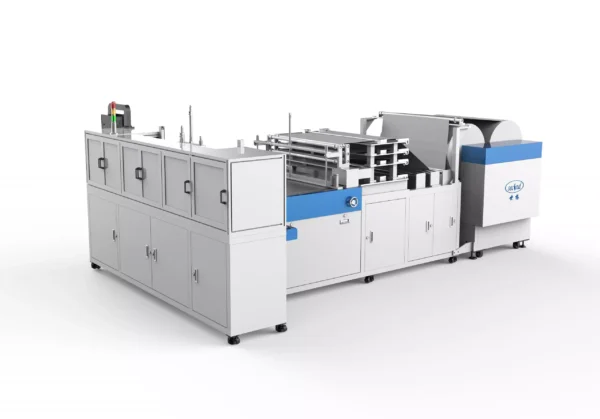

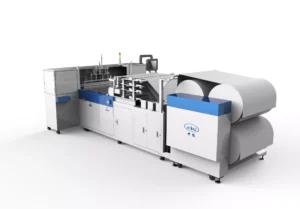

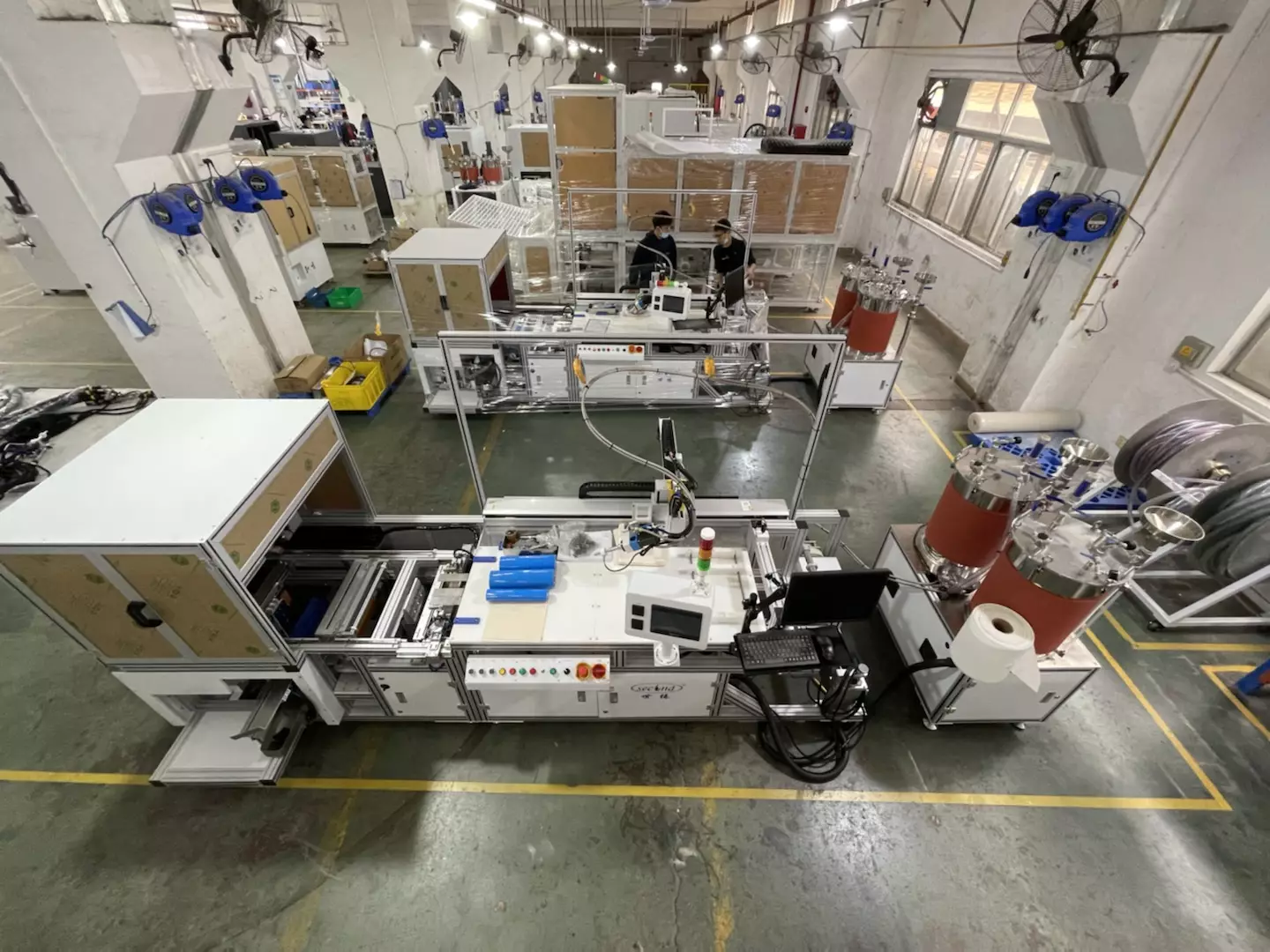

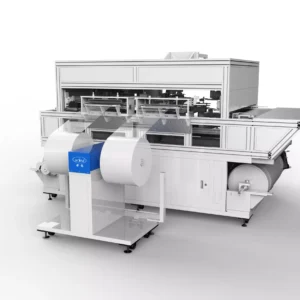

The equipment is suitable for the production process of household carbon block filter.

How it works?

2 operators will need to process the production, the machine can roll, and fabricate different sizes carbon block filters, adjustable and meet certain thickness materials. The equipment can be used for welding of the non-woven fabric and the central tube, winding of the carrier membrane, and allow to use 3-4 different materials to roll. After the rolling is completed, the equipment performs hot-press sealing and manual cutting. The system is reliable and efficient. It is also equip with safety light curtain to protect operators.

Application:

2 operators will need to process the production, the machine can roll, and fabricate different sizes carbon block filters, adjustable and meet certain thickness materials. The equipment can be used for welding of the non-woven fabric and the central tube, winding of the carrier membrane, and allow to use 3-4 different materials to roll. After the rolling is completed, the equipment performs hot-press sealing and manual cutting. The system is reliable and efficient. It is also equip with safety light curtain to protect operators.