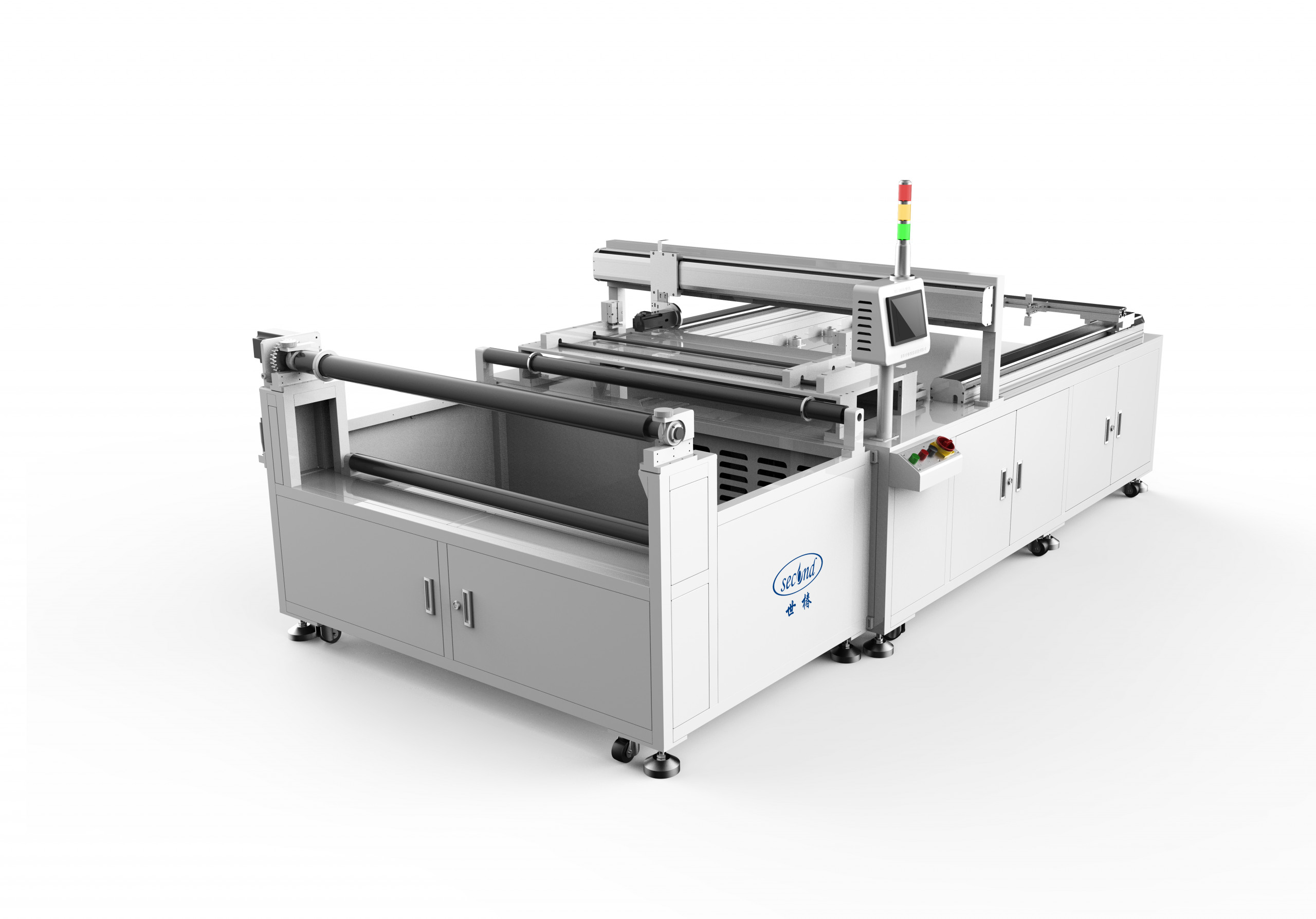

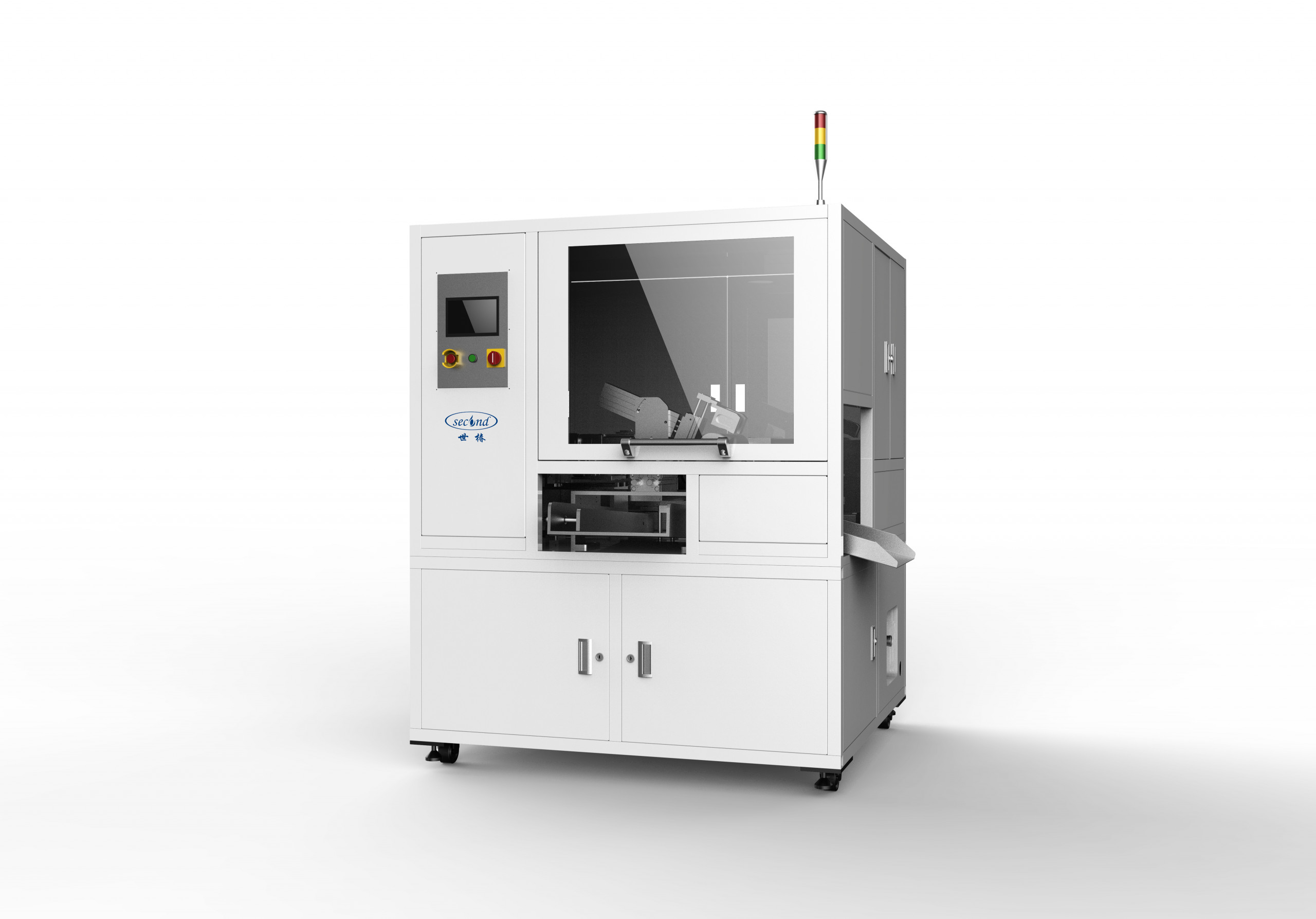

This is semi-automatic industrial reverse osmosis (RO) cartridge element rolling, it can roll SWRO, BWRO, 4040-8040 sizes of elements. It will need two people to operate at the same time. It is MMI type of machine, in the man-machine interaction area there’s safety light curtain installed for good protection. The machine comes with rolling table, adhesive dispensing, winding, ultra-sonic welding, and outer taping system, all in one. It is for mass production, and good for quick-change over to produce different sizes of the elements compare to the full-automatic machine.

Industrial RO cartridge element spiral winding machine SEC-S8040GL

Description

Equipment introduction:

The equipment is designed for different sizes of desalination, and commercial RO cartridge element fabrication needs. The machine was designed with solid structure that keeps precision, allows heavy usages, and years lasting. It equips and works with a high quality automated degassing, metering, mixing, and dispensing Cartesian robot. The machine has been sold world widely and proved with good reliability.

Features:

1- Equips with two-component AB glues automatic ratio mixing and potting system.

2- Semi automatic rolling desk.

3- Automatic outer taping machine.

4- Core pipe and carrier membrane ultrasonic welding system.

Application industry:

SWRO, BWRO water purification industry, RO cartridge element fabricating process.

Specification:

Model | SEC-8040GL | Description | Industrial RO cartridge element dispensing and spiral winding machine |

Suitable element | 4040-8040 | Mixing method | Static mixer |

Core tube loading method | Manual | Dispensing control system | Stepping motor + gear pump, servo motor + Ceramic piston pump |

Max working rang | 1300mm(X)*1500mm(Y)*500mm(Z) | Driving control system | PC + Motion control system, PLC |

Max speed | 0-500mm/s | Outer taping system | Automatic wrapping |

Repeat accuracy | ±0.025 | Capacity | 7PCS/H(8040) |

Mixing ratio | 1:1-5:1 | Power supply | AC380V 50HZ |

Mixing accuracy | ±2% | Power | 8KW |

Dispensing accuracy | ±2% | Weight | 1500kg |

Dosing accuracy | 1-15g/sec | Dimension | L2560mm*W4150mm*H2470mm |

General process introducction

The equipment is operated by 2 people at the same time. The core pipe and the carrier membrane will be welded together by on-board ultra sonic machine. The tricot (leaf) is manually insert into carrier membrane layers. The equipment automatically dispensing sealant and wind up step by step. The operating platform will raise up according to the increase in the number of layers of the tricot to keep the glued surface consistent. The wind system can provide stable and steady rolling up, while tension system is applied accordingly. It is also equip with safety light curtain to protect the interaction between human and robot. Please check our videos and contact us for details.

Material

The machine comes with automatic 2-parts AB adhesive material prepping system. The system equipes with two materials prepping tanks, they can perform degassing so to make sure the dispensing is bubble-free at all time. The system can manage various 2-parts materials with different ratios, such as 1:1; 5:1; 10:1 and so on, we can cusotmize to the materials' nautre. The material feeding system can prepare and feed the materials to the dispensing unit automatically. The materials can be mixing by ratio accurately and automatically to be dispensed. The dispensing is perform by a quality large dispensing range robot.

MANUFACTURING

In the Second Intelligent Equipment, we only build quality and heavy-duty SWRO, BWRO cartridge fabricating machine.

.jpg)

FAQ

We are direct manufacturer.

Generally, we pack our goods with proper wooden box. However, if client has special requirment, we can customize.

Depends on terms and conditions, negotiable.

Yes, we can produce according to the tested result. We can also product base on your design.

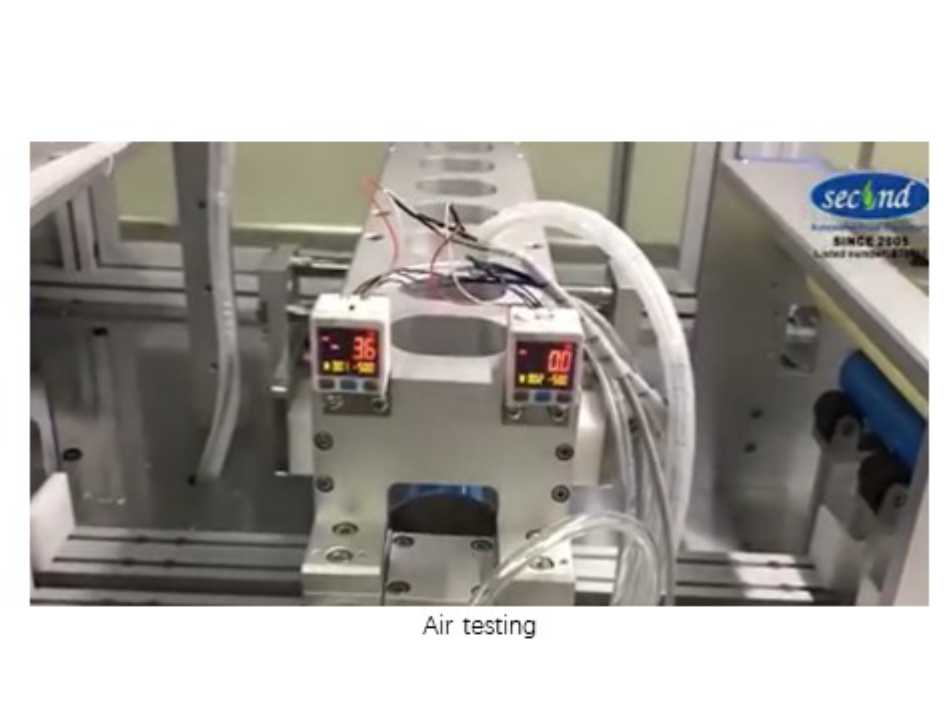

Yes, we will test 100% before delivery.

We keep good quality and competitive price to ensure our customers benefit. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Dispensing machine is an automatic machine and equipment that specializes in controlling fluid and dripping, coating, and potting the liquid on the surface of the product or inside the product. The glue dispenser is mainly used for glue and paint in the product process.

Glue dispensers are generally suitable for small products or electronic components, which are more precise; the products of potting dispensers are generally larger.

As long as it is a fluid with a viscosity within a certain range, it can be operated. The glue generally used in the dispenser includes red glue, hot melt glue, silica gel, grease and so on.

Technical Parameter

| Model | SEC-8040GL |

| Max working rang | 1300mm(X)*1500mm(Y)*500mm(Z) |

| Mixing method | Static mixer |

| Core tube loading method | Manual |

| Dispensing control system | Stepping motor + gear pump, servo motor + Ceramic piston pump |

| Driving control system | PC + Motion control system, PLC |

| Max speed | 0-500mm/s |

| Outer taping system | Automatic wrapping |

| Repeat accuracy | ±0.025 |

| Capacity | 7PCS/H(8040) |

| Mixing ratio | 1:1-5:1 |

| Power supply | AC380V 50HZ |

| Mixing accuracy | ±2% |

| Weight | 1500kg |

| Power | 8KW |

Main configuration:

| Description | Unit | QTY | Note |

| Driving motor | Set | 5 | Servo motor |

| Lead screw | Set | 5 | Taiwan Hiwin |

| Industrial computer | Set | 1 | Second Original |

| Monitor | Set | 1 | DELL |

| Operation system | Set | 1 | PLC,Weinview |

| Two component mixing valve | Set | 1 | Static valve |

| Precision metering pump | Set | 2 | Gear pump |

| Metering motor | Set | 2 | Stepping motor |

| Material tank | Set | 2 | 70L |

INQUIRY FORM