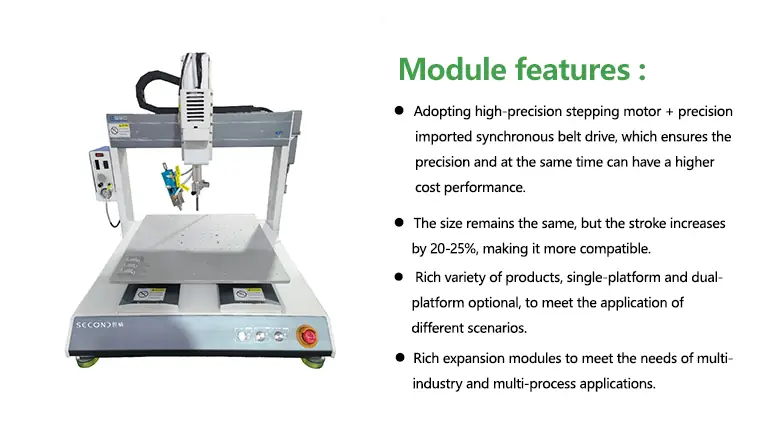

Feature:

Adopting stepper motor + precision imported synchronous belt drive, it can ensure high accuracy and have higher cost performance.

The size remains the same, but the travel is increased by 20-25%, making it more compatible

A wide variety of products, single platform and dual platform options to meet the needs of different scenarios

A variety of expansion modules to meet the needs of multiple industries and multiple process applications

Product features:

Aluminum alloy casting design, integrated molding processing, high strength, stable operation. Reduce the number of parts and improve assembly efficiency.

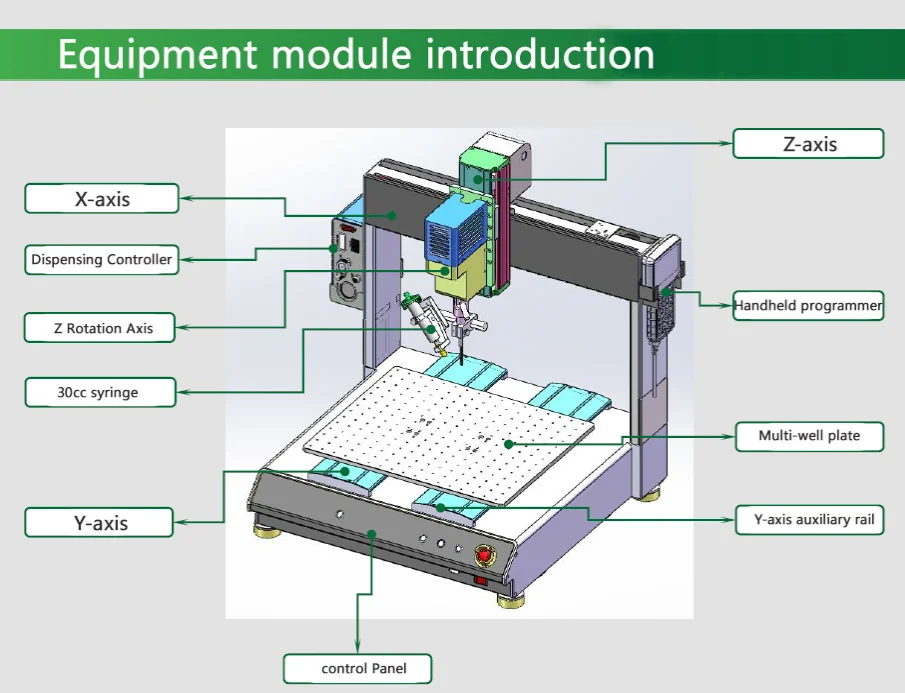

Detailed display diagram

Structure diagram

Product Description

Module features

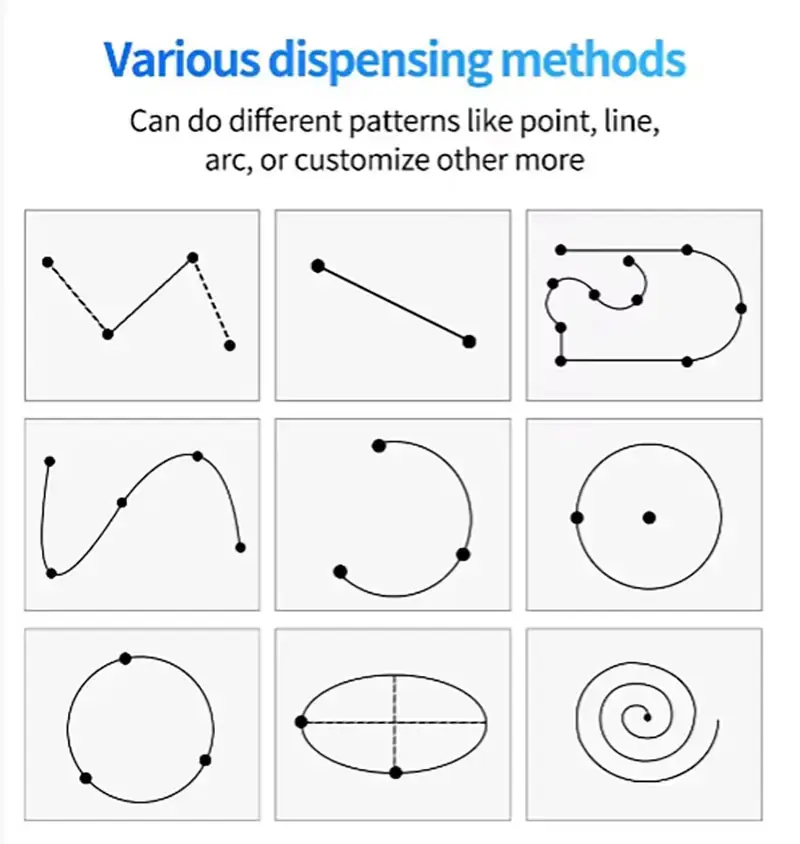

Dispensing process:

Multi-valve picture display

Applications:

Used in the fixing and protection of PCB electronic parts in the electronics industry, bonding of mobile phones, notebook shells, LCD glass, LED dispensing, optical lens dispensing, fabric material, paper packaging, automotive parts, and other hardware components to achieve the role of bonding and fixing.

Industry Applications: