Precision Conformal Coating Machine Series

These compact conformal coating machines enable highly advanced non-contact jetting for enhanced dispensing uniformity, throughout and material utilization. For higher-precision applications such as complex chip packaging, the powerful dispensing platform further boosts productivity with linear motor motion control. The smart in-line coating solutions, proven in the most advanced production environments, make it possible to handle a vast array of current and emerging products, assembly fluids and package types.

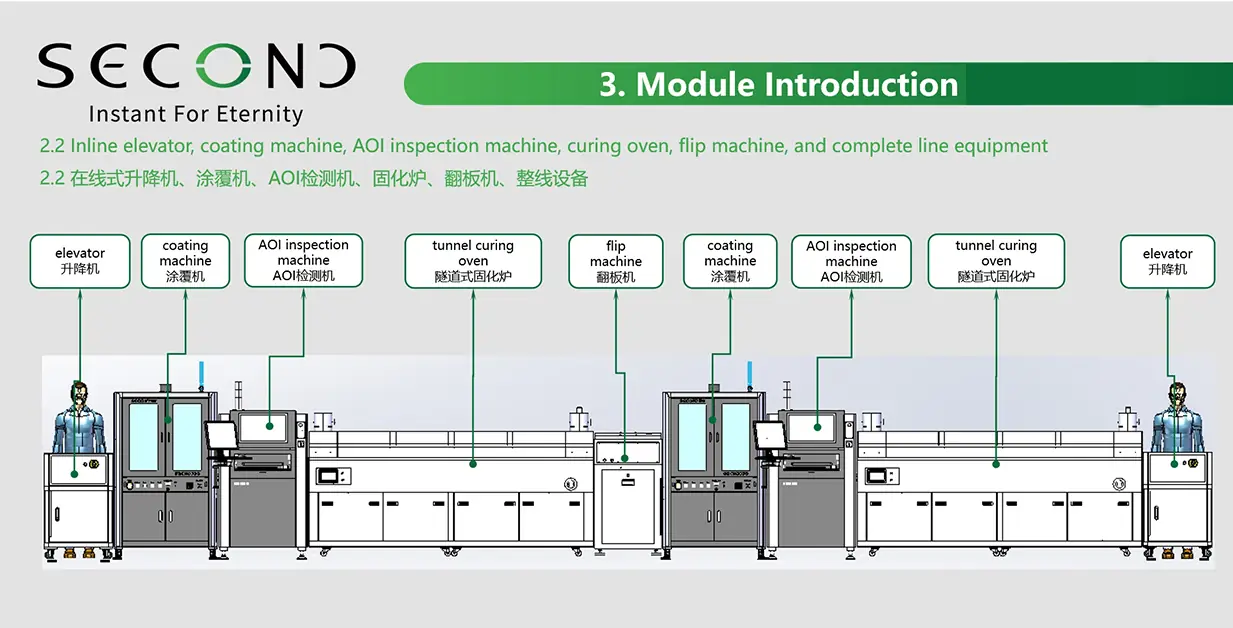

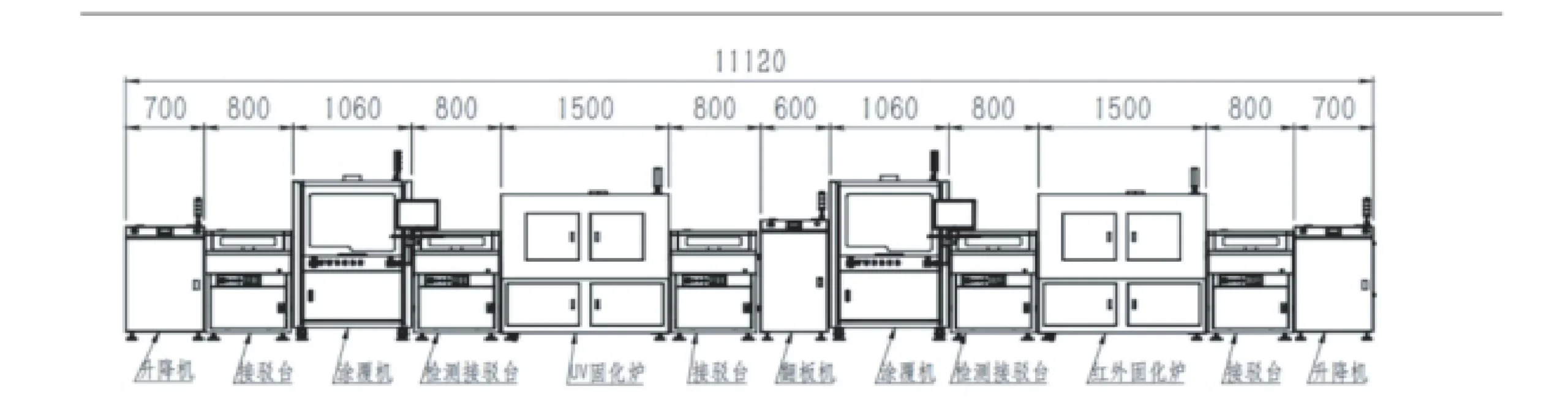

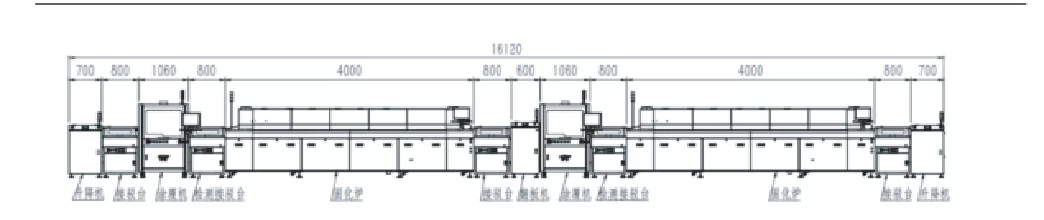

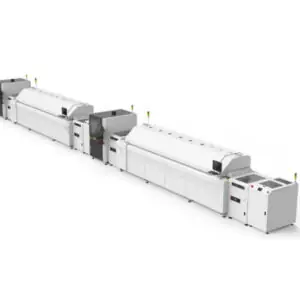

Fully automatic Coating – Liquid system, is a combination of different equipments, elevator, connecting table, inspection table, coating machine, hot air curing oven or UV oven, assembly line and so on.