Integrated line – 2-parts adhesive materials auto mixing and potting – vacuum casting, potting, encapsulating

Integrated line – 2-parts adhesive materials auto mixing and potting – vacuum casting, potting, encapsulating

The vacuum adhesive material potting, casting, encapsulating production line is mainly composed of 2-part materials automatic prepping and feeding machine, high power vacuum pump, product-prepping station with pallet-elevator, vacuum potting machine, curing furnace, product-collecting station with pallet-elevator, and an automatic pallet-circulate system. The production line adopts inline vacuumed chamber machine, it equips with three sets of automatic lifting doors to provide effective in-and-out products’ conveying, and has good air tightness. With these machines, it forms a high-level of automation adhesive materials casting system.

Inline vacuum box, and realize the functions of automatic glue filling, automatic pressure maintenance, vacuum glue bubble and other functions, equipped with good quality Germany join-venture technology vacuum pump, the pumping rate can reach 200m³/H, it helps speed up the cycle time and meets the high UPH capacity.

To better manage and control of the entire process and production, the system presets with MES interface, which allow for easy and effective connecting with the system to uploading details data. The data covers production quantity, equipment abnormality, abnormal time and other data, these are good for management and strategy review.

Supporting Systems

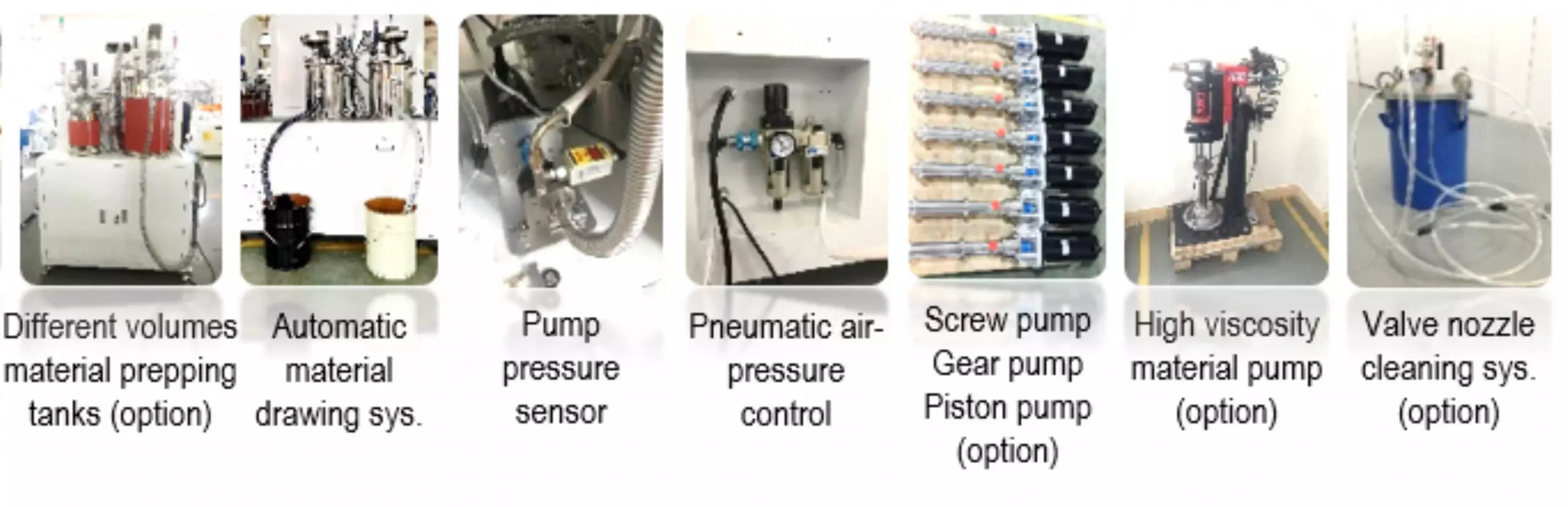

Material

Two parts silicone, resin, epoxy, polyurethane and other AB fluids, adhesive glues material that require to be automatic degassing, mixing, potting, casting base on ratio and dosing continuously, homogenously.

As two-component materials’ applications are getting more and more important for various types of manufacturing demands, the needs of the automated mixing and potting machines are increased also.

In this case, customer is using 2-parts AB adhesive materials to cast the electronic component for water, moisture, air, shock proofs, also heat dissipating as well as confidential design protection. After completed, we cut-off some units to check and see inside, the machine has done very good job in casting process, there’s no air-hole or material short-filling. The vacuum casting system equips with an automatic CNC Cartesian robot inside the vacuum box, onboard AB materials’ prepping tanks, and a powerful vacuum pump. Once the product is loaded, operator presses START button, the machine will shut the glass-door, automatic perform vacuuming, material feeding, the robot perform dispensing according to the trajectories till complete and released vacuum to open glass-door. The system is able to perform complete vacuum casting process automatically, and free the operator for other work

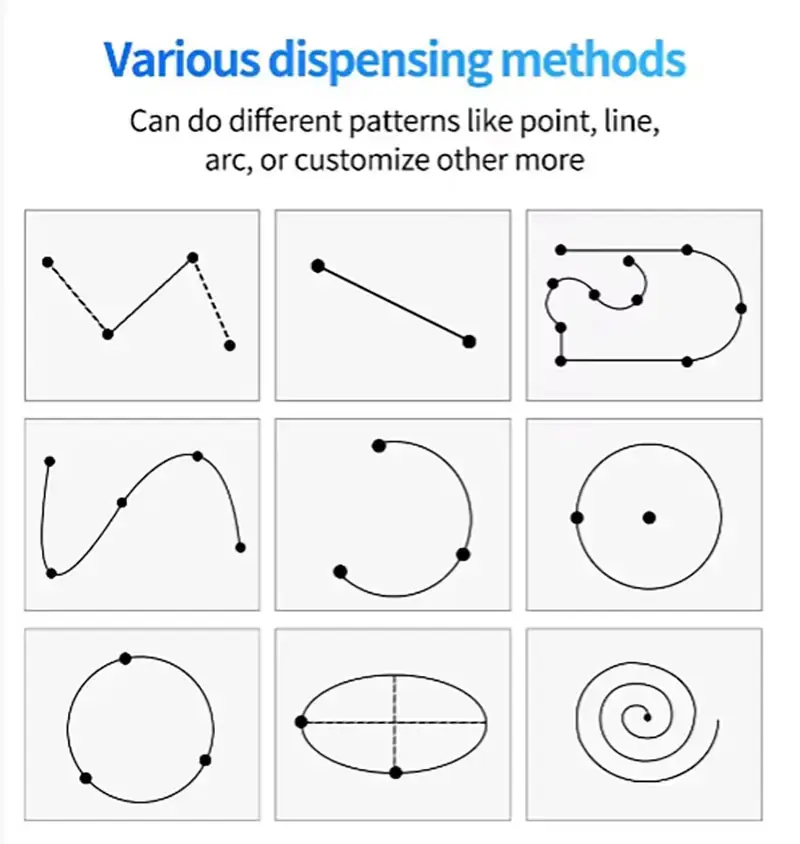

Dispensing process:

Commonly used glue

Multi-valve picture display

1 | Material automatic refill pump (automatic draw material into machine tank) |

2 | Degassing system (draw out air to make sure no bubble) |

3 | Upper and lower material level sensors (avoid too much or too little material) |

4 | Air filter (make sure incoming pressurized air is clean) |

5 | Buffer tank (catch accident spilled material) |

6 | Silica gel (for dehumidify) |

7 | Portable mixing head (allow to potting manually or adaptor to existing machine) |

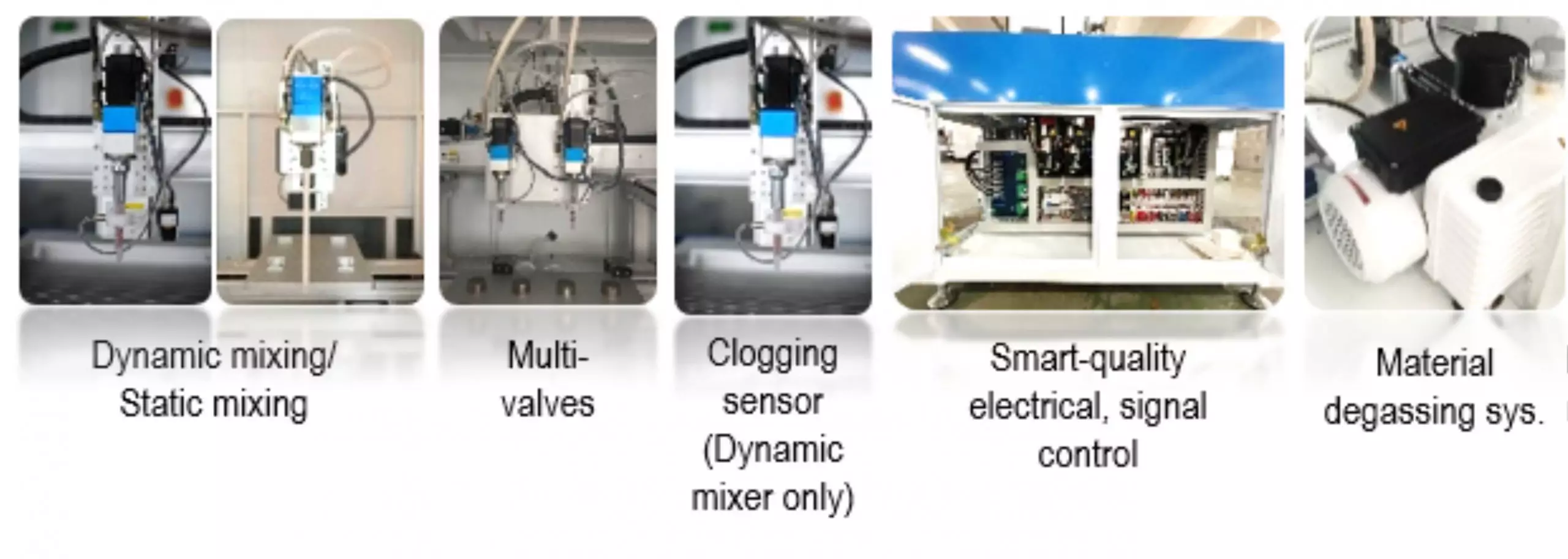

Additional configurations / functions list (these are options base on materials and production requirements with additional cost)

1 | Available in touch screen operation |

2 | Available in 15, 30, 70 liters tanks’ sizes (customize is welcome with additional cost) |

3 | Available in Dynamic or Static valve (depends on materials) |

4 | Agitate motor (tank stir) |

5 | Tank heating jacket (Silicone heater with auto regulator) |

6 | Heating hoses (depends on materials) |

*7 | Visual-assisting CCD camera, for simple trajectory design. When uses, operator do not need to look at nozzle, simply just look at the monitor to set the dispensing trajectory via the lens. (PLC control machine will not apply) |

8 | Mixing valve and mixing nozzle automatic flushing clean system |

9 | Pump pressure sensor (Monitoring the materials’ pump pressure, in case if over or under pressure, it will stop and alarm to alert) |

10 | Mixer tube clogging sensor (for dynamic valve, monitoring the mixing tube in case if clogged, it will alarm in 1-3 sec. to alert ) |

11 | Pump sizes, available in 3cc, 8cc, 12cc, 24cc, and so on… (it is determined by dosing speed, and volume) |

12 | Available in multiple dispensing valves or nozzles, such as 1, 2, 4, 6 |

13 | Secondary pumps (e.g. when transit material from a larger pump to a second pump with very small volume required, it is determined by the dosing volume) |

14 | Pallet or fixture (depends on) |

15 | Internet remote access (For PC computer model machine only) |

16 | Machine additional safety protection (Moving robot cover, or safety light curtain) |

Material

Two parts silicone, resin, epoxy, polyurethean and other fluids with big tanks or barrels of materials.

This machine is designed and built for the two components (2 parts) materials that need to be mixing together base on the ratio automatically. The machine equips with CNC automatic dispensing robot, which able to perform automatic dispensing efficiently and effectively without operator. The system comes with two tanks (15, 30, or 70 liters as the standard, option for custmization).

Control

1. The machine is user friendly, and operating by Window base software.

2.The software is design and developed by Second Intelligent.

3.With over 15 years in dispensing and potting, the software has included all of the functions that meets dispensing and potting needs. And it has been fine tuned and debugged well to provide good quality output.

4.The software has English instruction, and we welcome your language as well.

5.It is absolutely user friendly. With this computer system, it comes with an internet remote control access function, this allow us to help operator to conduct troubleshooting of the software, and can be used as an online instruction as well. It is welcomed, easy and helpful for international service and support.

Our two-component In-line automated vacuum potting system machine is often used in the LED driver, power supply dispensing, with this encapsulated process, the product is heat dissipation, moisture-proof, waterproof, and flame retardant.

EMI and FIP dispensing techniques are widely use in the telecommunication and transportation industries. With the rapid development of communications, electric vehicles, and personal wireless electronic gadgets, these products are often required to connect and interact between each others. However, the signals sometimes interfere with the others, so need to be filtered or shielded. To improve and control the electromagnetic signals, engineers can redesign the entire product, or it can apply EMI shielding materials to filter or shield. Shielding is relatively economical and easy to achieve, it is done basically by adding shielding gasket. Our dispensing machine can directly produce different sizes of triangular shapes or D-shape filtering gaskets, these gaskets can appear in different shapes and is directly applying to the products. The dispensing machine equips with special adhesive material dispensing valve to apply directly, and without post-processing. The machine is intelligent, precise, but user-friendly, without complicated installation, or setup. In addition to the above functions, this type of dispenser equipment can also dispense FIP adhesive glue, and thermal interface material. The equipment is not only precise, but also multi-purpose, which is convenient for various type of storage battery, and electronic product applications.

Dispensing equipment are important for various EMS (electronic manufacturing service) productions. Electronic product processing service industry is indispensable to modern life, because many products are now equips with electronic and become more intelligent. These products are becoming more and more complex, precise and tiny in size. And for consumer product, their production volume also in large production and fast turnover. Therefore, it is necessary to use automated equipment, or even fully automated production lines to produce to meet apply the materials. With the automatic dispensing robots, it is possible to catch up with the capacity and demands. And more importantly, to improve economic efficiency to maximize economic of scale, and so to reduce unit prices to enhance competition. Very often in this type of production, the uses of dispensing machines or equipment is inseparable. In this production process, the glue dispenser is usually used to assist in the functions of fixing, connecting, protecting, dissipating heat and so on between parts and components. Our glue dispensers can directly add the relevant materials to the specified positions accurately and quickly as required.

Two-component materials’ encapsulating and casting production are important to enhance electronic products. No matter if your product is for business selling, or for household consuming, nowadays everyone has higher quality requirements and expectations. Furthermore, the protection of the product is not only to optimize the function of the product, but also to prolong the service life of the product, thereby reducing production waste. In electronic products the parts and components are generally composed of different metals and sensitive chemical combined materials. The more precise the product, the more high-tech the product it is, with this, it requires higher protection, so that it can be optimized according to the requirements. In doing so, it can state of long-term operation without being affected by the surrounding environmental conditions. Our two-component potting machines are specially designed for this production, as well as our vacuum encapsulating and casting potting machines. These machines can accurately degas the two-component adhesive materials base on the ratio, meter, mix, and homogenously and continually to the products. These materials cannot be applying manually, they need to use machines, which can be supplied in large quantities, continuously, accurately, and for long time of works. With the materials provided by such equipment, the product will have better protection, heat dissipation, waterproof, moisture-proof, encryption (to protect the circuitry design, and components used).

We are direct manufacturer.

Generally, we pack our goods with proper wooden box. However, if client has special requirment, we can customize.

Depends on terms and conditions, negotiable.

EXW, FOB,CIF…

Yes, we can produce according to the tested result. We can also product base on your design.

Yes, we will test 100% before delivery.

We keep good quality and competitive price to ensure our customers benefit. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Dispensing machine is an automatic machine and equipment that specializes in controlling fluid and dripping, coating, and potting the liquid on the surface of the product or inside the product. The glue dispenser is mainly used for glue and paint in the product process.

Glue dispensers are generally suitable for small products or electronic components, which are more precise; the products of potting dispensers are generally larger.

As long as it is a fluid with a viscosity within a certain range, it can be operated. The glue generally used in the dispenser includes red glue, hot melt glue, silica gel, grease and so on.

Yes. Dual-fluid models with 1:0.8~1:1.2 mixing ratio control are available.

0.1mm diameter with ultra-fine nozzles (requires low-viscosity fluids).

CE, UL, ISO 9001, and RoHS compliance for global markets.

Yes. Dual-fluid models with 1:0.8~1:1.2 mixing ratio control are available.

3C electronics, EV batteries, LED packaging, solar panels, and biomedical devices.

EC series machine performance:

CCD video-assisted programming, large field of view to take pictures as a whole, automatic identification of product location.

Independently researched and developed R-axis needle head linkage rotation function, equipped with ceramic rotary valve, which is absolutely leading in the application field of conductive adhesive.

Gantry dispensing platform can be equipped with a variety of glue supply systems to meet multi-process and realize one machine with multiple uses.

The online dispenser can be flexibly equipped with automatic width adjustment, memory, weighing, code scanning, improve the information management level of the entire line of equipment.

This E-380S dispensing robot works with 50ml 2-part adhesive materials servo mixing and dispensing valve. The machine is using volumetric measurement technology, the AB glues are mixing and dosing out of the cartridge at precise, and uniform speed. The servo-motor-extruder is able to give strong pressure to push the materials out in right volume to mix and dose, works especially good for high viscosity two-component AB materials. This is professional, heavy-duty industrial adhesive fluid, glue automated desktop dispensing machine.

This is a 30cc hot melt adhesive dispensing machine. It works with one-piece aluminum casted Cartesian robot body, it is strong structure and stable operation. The machine has compacted, but with bigger working range, 380x380x100mm XYZ. The dispenser equips with ceramic heating barrel, and one pre-heater for effectively and efficient work. The heating controller works with a digital temperature control, can be accurately controlled to ± 1 ℃. This is professional, heavy-duty industrial adhesive fluid, glue automated desktop dispensing machine. Besides 30cc packaged hot-melt dispensing machine, we also provide different volumes of hot-melt dispensing system, such as 100cc, 10 liters and others.

This E-380S Automatic glue dispensing robot works with 400ml 2-part adhesive materials servo mixing and dispensing valve. The machine is using volumetric measurement technology, the AB glues are mixing and dosing out of the cartridge at precise, and uniform speed. The servo-motor-extruder is able to give strong pressure to push the materials out in right volume to mix and dose, works especially good for high viscosity two-component AB materials.