Feature:

- IPC + Second intelligent motion control card integrated with advancedalgorithms, together with high-precision three-axis manipulator,realizes three-dimensional high-speed and precise movement.

- Using German vacuum pump, it has fast pumping speed and low noise.The vacuum chamber has high sealing performance and the vacuumdegree can be adjusted independently to ensure that the product isbubble-free.

- Adopting a two-stage valve design, the glue outlet head will not drip orleak glue in a vacuum environment; it is equipped with a fullyautomatic cleaning module that can clean the valve and mixing part,making the operation

- Inline potting and rail conveying can be connected to equipment suchas docking stations and curing ovens to achieve fully automaticassembly line operations.

- Through precise control of the metering motor, it can achieve preciseproportioning, automatic mixing and automatic potting of two-component glue.

- With vacuum feeding, vacuum degassing, optional heating, stirring,automatic cleaning, pressure monitoring and other functions, can copewith a variety of complex glue environment.

PRODUCT DETAILS

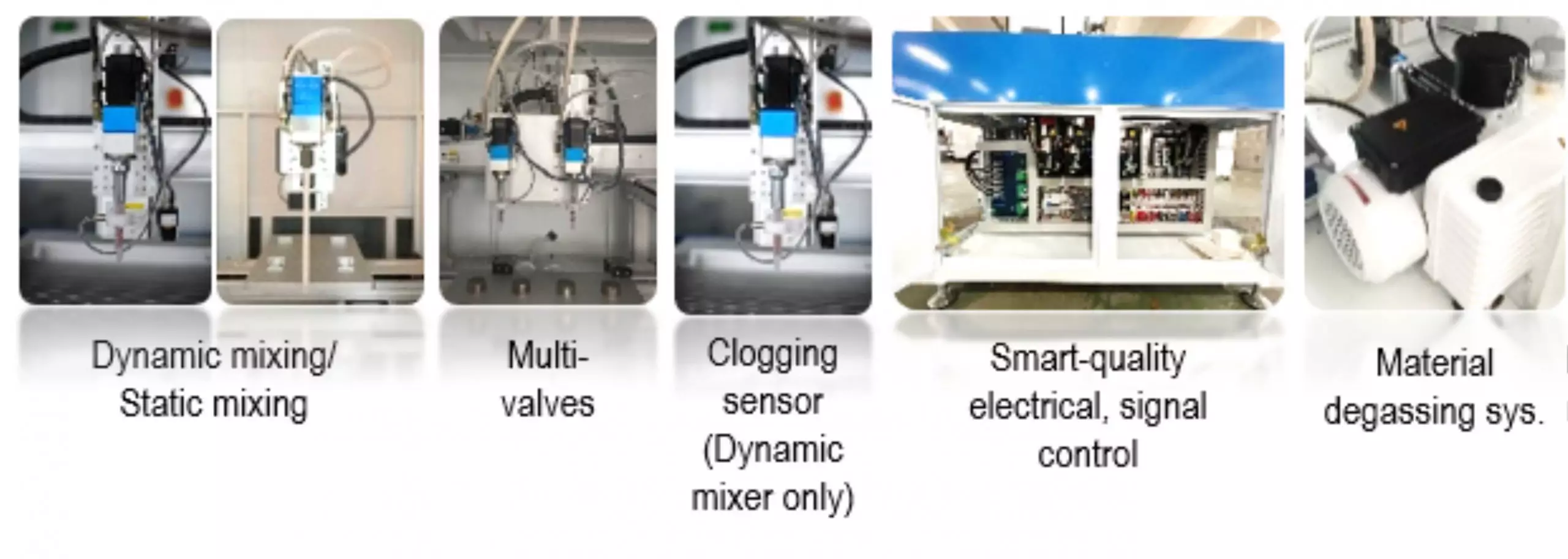

Supporting Systems

Material

Two parts silicone, resin, epoxy, polyurethane and other AB fluids, adhesive glues material that require to be automatic degassing, mixing, potting, casting base on ratio and dosing continuously, homogenously.

MANUFACTURING

As two-component materials’ applications are getting more and more important for various types of manufacturing demands, the needs of the automated mixing and potting machines are increased also.

CASE

CASE

In this case, customer is using 2-parts AB adhesive materials to cast the electronic component for water, moisture, air, shock proofs, also heat dissipating as well as confidential design protection. After completed, we cut-off some units to check and see inside, the machine has done very good job in casting process, there’s no air-hole or material short-filling. The vacuum casting system equips with an automatic CNC Cartesian robot inside the vacuum box, onboard AB materials’ prepping tanks, and a powerful vacuum pump. Once the product is loaded, operator presses START button, the machine will shut the glass-door, automatic perform vacuuming, material feeding, the robot perform dispensing according to the trajectories till complete and released vacuum to open glass-door. The system is able to perform complete vacuum casting process automatically, and free the operator for other work.

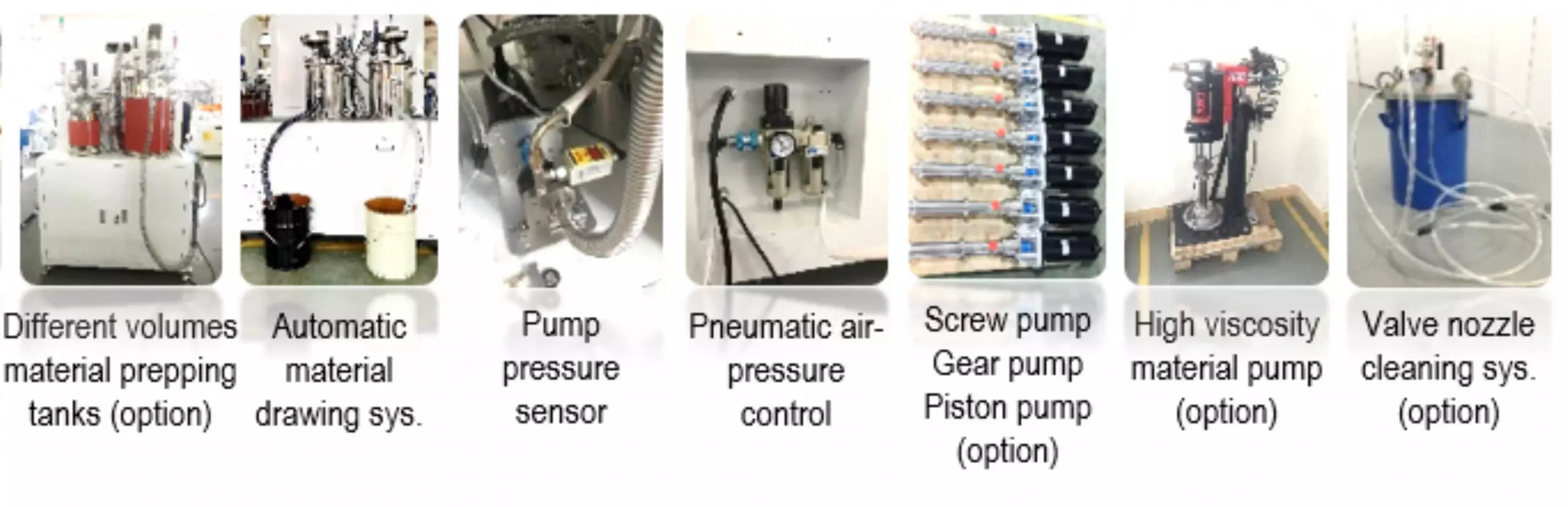

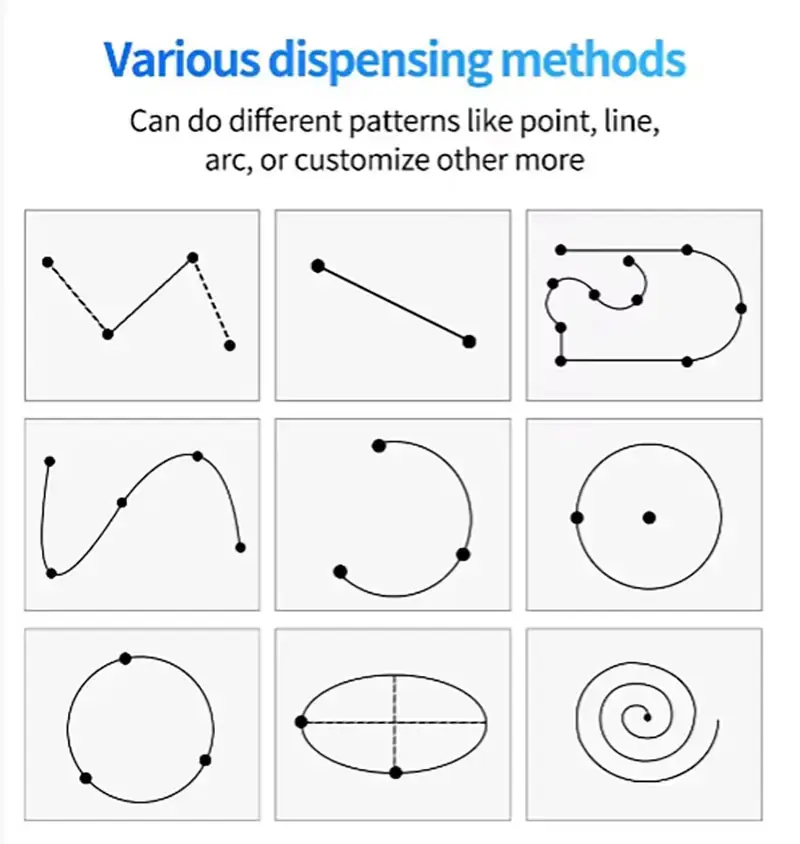

Dispensing process:

Multi-valve picture display

Application :

Automatic potting in a vacuum environment has high product requirements and isusually used in automobile manufacturing, capacitor coils, transformers, relays, powersupplies and other industries.

Advantages

- Capable of working with high viscosity, extreme ratio AB materials that allows to save lot of costs.

- With the system, it improves the casting, enrapturing output quality.

- System equips with an inline conveyor to provide high level automation.

- Flexible machine designed for easy set-up, suitable for various scale of productions.

- Easy for production operating and managing.

Industry Applications:

SOLUTION

Material

Two parts silicone, resin, epoxy, polyurethean and other fluids with big tanks or barrels of materials.

This machine is designed and built for the two components (2 parts) materials that need to be mixing together base on the ratio automatically. The machine equips with CNC automatic dispensing robot, which able to perform automatic dispensing efficiently and effectively without operator. The system comes with two tanks (15, 30, or 70 liters as the standard, option for custmization).

Control

1. The machine is user friendly, and operating by Window base software.

2.The software is design and developed by Second Intelligent.

3.With over 15 years in dispensing and potting, the software has included all of the functions that meets dispensing and potting needs. And it has been fine tuned and debugged well to provide good quality output.

4.The software has English instruction, and we welcome your language as well.

5.It is absolutely user friendly. With this computer system, it comes with an internet remote control access function, this allow us to help operator to conduct troubleshooting of the software, and can be used as an online instruction as well. It is welcomed, easy and helpful for international service and support.

-300x300.webp)