Copyright © 2025 Shenzhen Second Intelligent Equipment Co., Ltd All rights reserved.

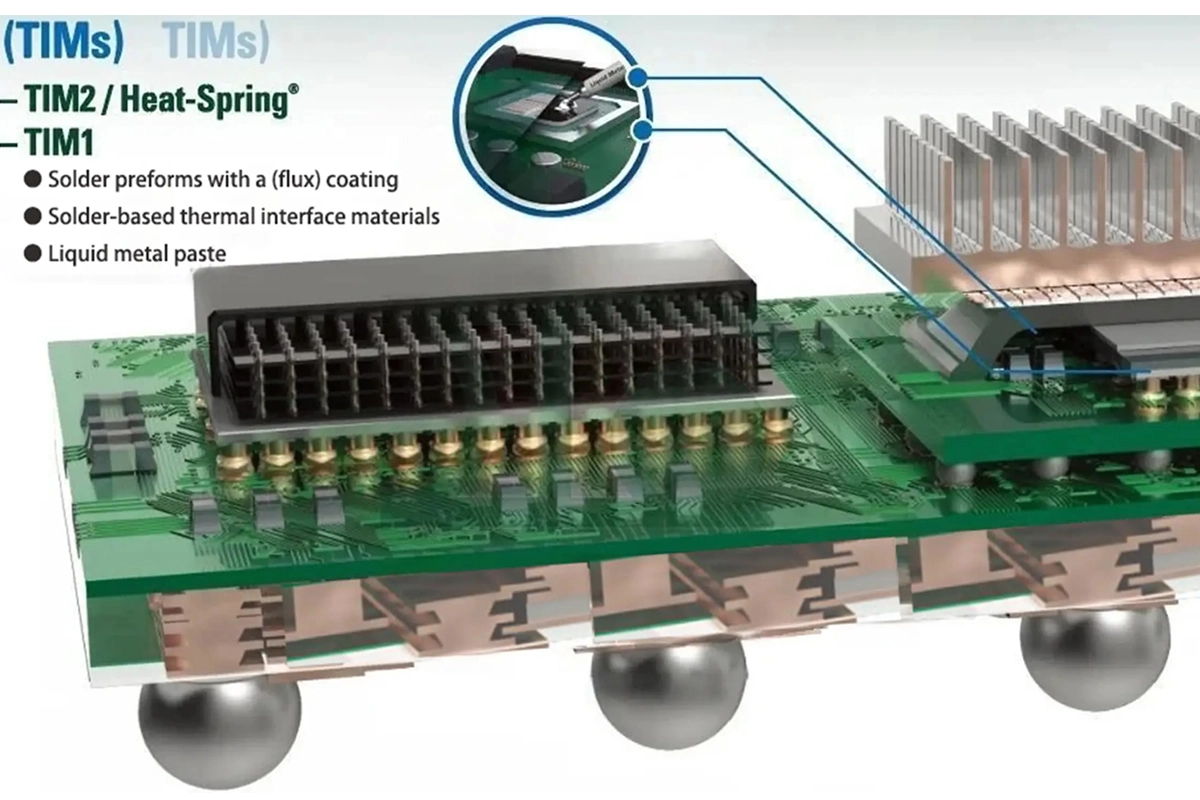

The CIPG/FIPG thermal paste dispenser is an automated device specifically designed for the precise application of thermal interface materials (TIMs), primarily used for heat management in electronic products. The CIPG/FIPG thermal paste dispenser’s application characteristics can be summarized as follows: It uses a highly automated and intelligent method to stably, consistently, and efficiently apply high-viscosity, high-performance thermal paste in a pre-set, precise three-dimensional pattern to the designated locations of complex electronic products. Deeply integrated with automated production lines, it ultimately aims to achieve a reliable, repeatable, and efficient heat dissipation assembly process in large-scale manufacturing. These features make it a critical piece of equipment for ensuring the thermal reliability and production quality of high-end electronic products.

Automatic feeding by platen pump + Glue processing in transit tanks

+ piston pump for metering + Dispensing Valve

The lithium battery cell coating process is a precise and continuous core manufacturing process. Its core lies in coating the positive and negative electrode slurries of the battery onto the metal foil current collector with extremely high consistency and a preset thickness through precise methods such as slit extrusion. The coating is then immediately placed into a segmented temperature-controlled oven for drying to cure the coating and evaporate the solvent. The entire process ensures that the areal density, blank size and surface quality of the electrode sheet are uniform and stable through fully automatic tension control, online real-time thickness measurement and defect detection, thereby preparing a reliable and defect-free electrode substrate for subsequent processes.

RTV effectively suppresses the movement of plug-in components.

●The glue dispensing and testing machine is used for mobile phone narrow frame spray glue dispensing, tablet shell, notebook screen;

●keyboard and other fully automatic glue dispensing operations, mainly completing automatic cleaning of the glue dispensing surface;

●automatic glue dispensing/spraying, automatic testing, NG sorting and other processes and procedures;

●The platfomm and X/Y module base are made of mineral casting, and the

key surfaces are processed by grinding to ensure higher precision and

sta bi lity.

●Gantry type structure, withstand large loads, stable structure, and

●Powerful vision positioning system, can meet the Mark point positioning.

grasping edge positioning, 3D scanning positioning.

●Strong expandability, can extend the AOl inspection 3D inspection, UV

exposure curing and other functions.

●Powerful platfomm compatibility, contact and non-contactdispensing.

single-head and multihead synchronized dispensing, automatic compensation and adjustment of the distance between the two heads,five-axis dispensing function basedon the needle Ay’R displace ment, etc.

Performance:

Simple and practical, easy to program, realize automatic dispensing operation at the most economical price

Economical double Y platform:

■ With higher flexibility

■ Alternate operation to improve production efficiency

■ Powerful application expansion module, more extensive application

■ Expandable double Y double rotation to achieve six-axis alternate dispensing function

● Adopting stepper motor + precision imported synchronous belt drive, it can ensure high accuracy and have higher cost performance.

● The size remains the same, but the travel is increased by 20-25%, making it more compatible

● A wide variety of products, single platform and dual platform options to meet the needs of different scenarios

● A variety of expansion modules to meet the needs of multiple industries and multiple process applications

Do not hesitate to contact us for further information, thanks in advance for your support!