Feature:

● Intelligent glue control

Independent research and development of control software, easy to operate, CCD vision-assisted programming, metering control is precisely adjusted from 10:10 to 10:1.

● Core craft

The combination of multiple metering pumps meets the application of different glues; the maintenance-free two-liquid dynamic mixing valve solves the problems of leakage, blockage, sealing and other losses.

● Micro control

Independent research and development of micro piston pump, high precision, automatic proportioning, automatic mixing.

● Automatic alarm

Real-time monitoring of the mixing status, discover problems in time, and eliminate defective products.

PRODUCT DETAILS

Detailed display

Structure diagram

MANUFACTURING

- User friendly bilingual (Chinese/English) touch screen human interface, easy to learn and understand, can store 100 sets of glue parameters;

- The filling speed, the filling time and the stopping time can all be parameterized, the amount of glue is stable, and the glue is not leaked;

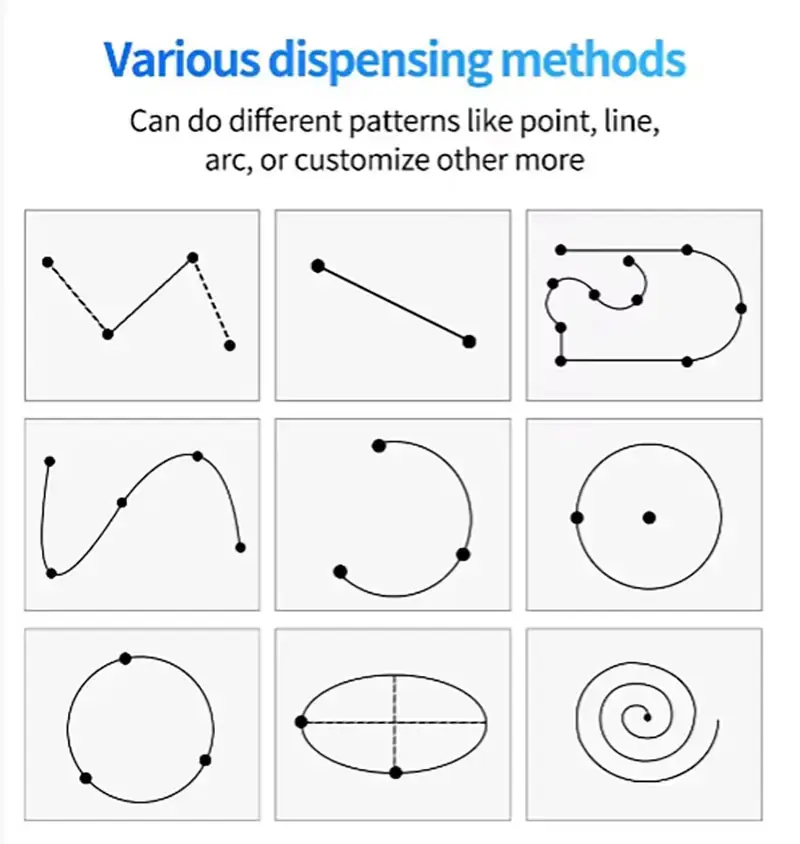

- It has the functions of point, line, surface, arc, circle and three-axis linkage, which can adapt to any irregular object filling;

- saving labor, one device can reach the output of traditional 5-6 people;

- according to the need ratio, to achieve side mixing while filling glue, to maximize the savings of glue;

- Two tanks store material nindependently, avoid materials caking, and increase storage time;

- the unique control system, not affected by the pressure mfactor, to avoid uneven rubber, drawing, air bubbles and other phenomena;

- The storage tank is equipped with a liquid level sensor switch, with Automatic material shortage alarm;

- Optional glue stirring, heating and vacuum defoaming function, suitable for different kinds of infusion process.

Dispensing process:

Multi-valve picture display

Application :

Two component Automatic Adhesive Potting Machine SEC-S3030C are designed for multi purposes dispensing. One machine can adapts and use different dispengsing valves and feeding systems. With this function, you can save cost and increase efficiency

Inline automatic glue filling, high degree of automation, all kinds of two-component glue, electrical (wire) road board industry, electronic components industry, electric light source industry, small household appliances industry, igniter industry, vehicle supplies industry, vacuum cleaner industry, filter industry and many other fields

Material ref.:

UV glue, AB glue, EPOXY (black glue), white glue, EMI conductive glue, silicone, RTV, epoxy resin, instant glue, silver glue, red glue, solder paste, thermal paste, solder mask paste , clear paint, screw fixer, etc.

Benefits:

- This is a compact machine but with flexible design to meet various daily small to medium scale of encapsulating production.

- Reduces materials waste or product waste.

- Easy for production operating and managing.

- User-friendly and low maintenance machine.

Industry Applications:

Suitable for various needs in the dispensing industry: common glues such as UV glue,red glue,silver glue,ABglue,COB black glue,conductive glue,Epoxy Resin,Silicones,heat dissipation aluminum paste,instant glue,etc

SOLUTION

Material

Two parts silicone, resin, epoxy, polyurethean and other fluids with big tanks or barrels of materials.

This machine is designed and built for the two components (2 parts) materials that need to be mixing together base on the ratio automatically. The machine equips with CNC automatic dispensing robot, which able to perform automatic dispensing efficiently and effectively without operator. The system comes with two tanks (15, 30, or 70 liters as the standard, option for custmization).

Control

1. The machine is user friendly, and operating by Window base software.

2.The software is design and developed by Second Intelligent.

3.With over 15 years in dispensing and potting, the software has included all of the functions that meets dispensing and potting needs. And it has been fine tuned and debugged well to provide good quality output.

4.The software has English instruction, and we welcome your language as well.

5.It is absolutely user friendly. With this computer system, it comes with an internet remote control access function, this allow us to help operator to conduct troubleshooting of the software, and can be used as an online instruction as well. It is welcomed, easy and helpful for international service and support.