This is automated industrial adhesive material dispensing robot works with turntable dispensing robot SEC-NRB700-UR

Copyright © 2025 Shenzhen Second Intelligent Equipment Co., Ltd All rights reserved.

DH Series Cantilever In-Line Automated Dispensing Systems Platforms:

● Large stroke dispensing for large product length and width

● Powerful expansion capabilities for ion cleaning, dispensing, testing UV exposure, etc.

● Powerful feature

● Rich Configuration

● Smart

● Wide range of application

High scalability, high compatibility, suitable for screw stack production – SEC – Stacking machine system – Screw-type

The goal of designing the screw stacking line is to develop a fully automatic assembly line for the stacking and assembly of PEM hydrogen fuel cell screw stacks. The loading and unloading of wire/cable and materials is achieved by robots. The stacking of stack end plates, current-collector plates, bipolar plates and other materials is completed by robots. The high-precision servo pressing system to ensures the precise pressure of the stack, the CCD visual alignment system ensures the accuracy, the studs are manually locked, and the multi-directional air tightness test of the stack is carried out by the flow method accurately.

This is automated industrial adhesive material dispensing robot works with turntable dispensing robot SEC-NRB700-UR

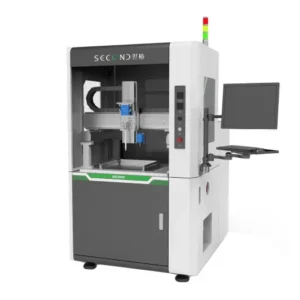

Micro potting machine/SEC-S400-BH/SEC-S500-BH

• High-speed and stable three-axis motion platform

• Micro potting, high precision

• Rich configurations and wide application

The equipment is suitable for the production process of household activated carbon block filter, it can roll different layers of ACF, and PP filters.

Floor-standing platform performance:

● CCD visual programming precise positioning, visual correction, improve programming efficiency and dispensing accuracy;

● Chinese and English operating system, clear software interface layout, simple operation, easy to learn and understand;

● Support visual inspection, integrated control of dispensing and visual inspection, one machine for multiple uses, effectively control dispensing yield;

● Can be equipped with a line laser scanner for 3D path guidance to achieve flexible dispensing;

● The software can support a variety of dispensing systems and functional module applications, such as automatic needle alignment, automatic height measurement, dispensing weighing compensation, five-axis linkage and other functions,

effectively overcome the difficulties of various dispensing processes and help improve dispensing quality;

This machine is suitable for UV-packaging, hot melt adhesive dispensing robot bonding, epoxy bottom filling (underfill) and other precision dispensing processes.