Dispensing Machine Application Case for RTV Silicone (Loctite SI 5910)

Application Background

RTV silicone dispensing is widely used in automotive and industrial sealing applications for waterproofing, dust protection, and vibration damping.

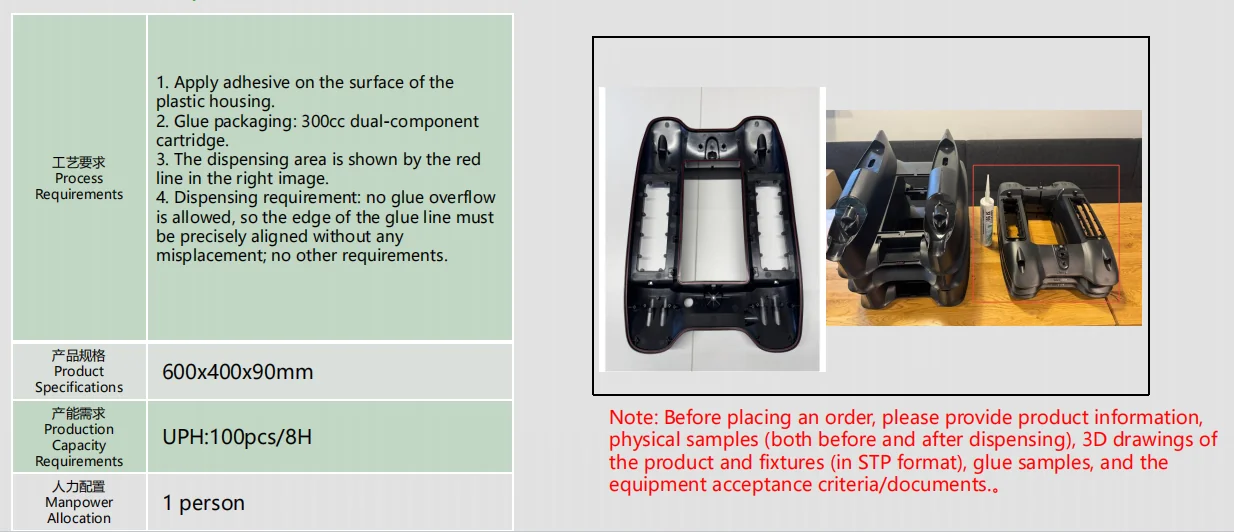

In this case, the customer’s product is a housing-type structural component with strict requirements for bead appearance and consistency.

Production Requirements:

– Target capacity: ≥ 100 pcs/hour

– Adhesive: Loctite SI 5910 RTV Silicone

– Dispensing requirements:

– Consistent and continuous bead

– No stringing or overflow

– Uniform bead despite product height variations

Initial Setup and Challenges

Initial dispensing was done using a standard syringe package with pneumatic pressure dispensing.

This setup caused several issues during production:

– Insufficient pressure for medium-viscosity RTV silicone

– Slow dispensing speed, unable to meet 100 pcs/hour

– Inconsistent bead width due to air pressure fluctuation

Conclusion:

Standard syringe + pneumatic dispensing is not suitable for medium-viscosity RTV silicone in high-throughput production.

Optimization Step 1: Piston Dispensing System

To improve output force and dispensing speed, the system was upgraded to a piston (pressure cylinder) dispensing solution.

Key improvements:

– Stable and continuous dispensing pressure

– Significantly higher dispensing speed

– Shorter cycle time

Result:

Overall dispensing efficiency increased by approximately 2x, allowing the system to reach the target capacity of 100 pcs/hour.

New Challenge Identified: Inconsistent Product Height

After improving speed, another issue became apparent:

Due to molding and tolerance variations, product height was inconsistent across parts.

With a fixed Z-axis dispensing height, this caused uneven bead width and height, which was unacceptable for sealing quality and appearance.

Final Optimization: Laser Height Detection Module

A laser height sensor was integrated into the dispensing system.

Working principle:

– Automatically scans product height before dispensing

– Dynamically compensates Z-axis position in real time

– Maintains a constant nozzle-to-surface distance

Final results:

– Uniform bead width and height

– Improved sealing performance

– Enhanced visual appearance

Before and After Comparison

Before:

– Syringe + pneumatic dispensing

– Slow speed

– Unstable bead quality

After:

– Piston dispensing system

– Laser height detection

– Stable, uniform, and high-efficiency dispensing

Solution Summary

Initial setup:

– Syringe-based pneumatic dispensing

– Low efficiency and inconsistent quality

Optimized solution:

– Piston dispensing system for RTV silicone

– Laser height compensation for height variation

Final performance:

– Capacity ≥ 100 pcs/hour

– Consistent bead quality

– Suitable for medium- to high-viscosity RTV silicone

Applicable Industries

– Automotive components sealing

– Industrial enclosures

– Home appliance housings

– RTV silicone dispensing applications

Conclusion

In RTV silicone dispensing, proper system selection is critical.

By combining a piston dispensing system with laser height detection, both productivity and dispensing consistency were significantly improved.

If you are using Loctite SI 5910 or similar RTV silicone and facing issues such as slow dispensing speed, unstable bead quality, or insufficient capacity, a customized dispensing solution can effectively resolve these challenges.