Second Intelligent In-Line Vacuum Glue Potting Machine: A Tool for High-Quality and High-Efficiency Glue Filling

In-line vacuum glue potting machine is a kind of efficient and precise equipment, which is mainly used for vacuum potting of products with glue under vacuum environment. Under the current background of industrial automation, more and more factories start to use vacuum glue potting machine to equip their production.

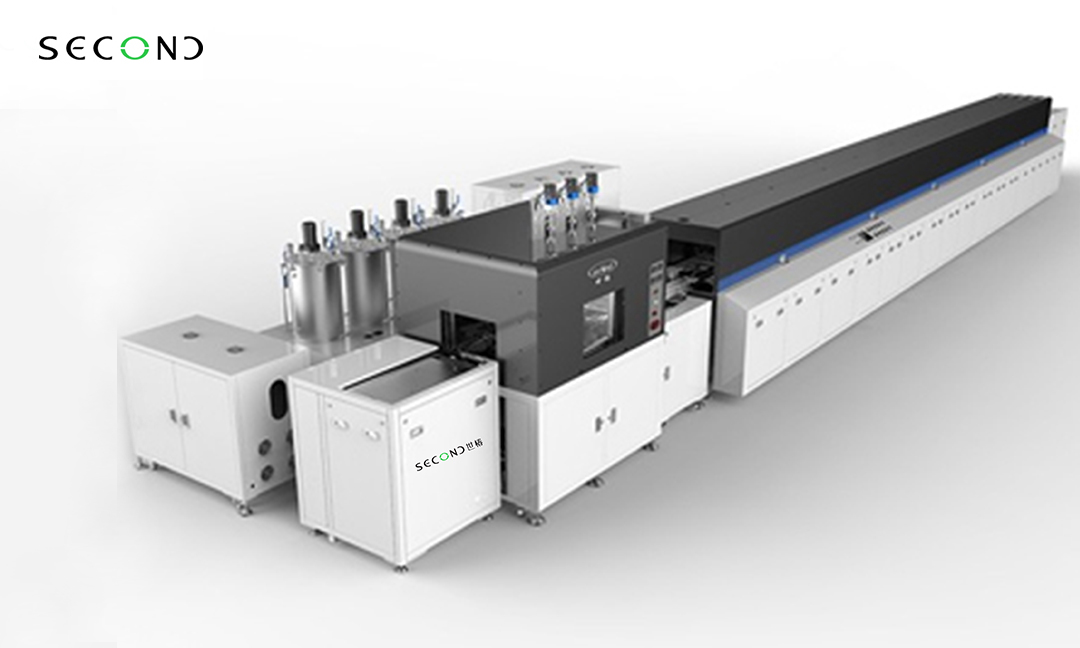

In front of the extensive market demand, Shenzhen Second Intelligent Equipment Co., Ltd (referred to as Second Intelligent) combines its own precision assembly technology advantages and industry development trend, developed and upgraded the in-line vacuum glue potting machine SEC-S400-ZL which is suitable for automotive electronics, capacitors, new energy motors, high-voltage packages, ignition coils, solenoid coils, motor stators and sensors, and other industries, which is a good solution to the problem of The industry commonly exists in the product of small seams, poor penetration and easy to produce bubbles when filling glue and other issues, and in the stability and performance of the product have a strong industry advantage.

In-Line Vacuum Glue Potting Machine

1.Promote the continuous advancement of the vacuum potting machine

With the continuous progress of science and technology and the continuous development of various industries, the demand for gluing equipment grows, the application scenarios also tend to be more diversified. In the glue potting machine market, semi-automatic glue potting machine has been China’s largest demand for products, but benefited from the downstream automation degree of enhancement.

Automatic glue potting machine market demand is also growing steadily. The market requirements for the gluing process is also more stringent, high precision, high efficiency, automation and even intelligence is still the direction of modern gluing equipment technology innovation.

Vacuum potting process can effectively improve product quality, production efficiency and automation level. Looking around the world, in-line vacuum glue potting machine is widely used, the market sales show a rapid growth trend. Second Intelligent, which has been ploughing into the fluid application industry for 19 years, has a keen grasp of the user’s advanced needs.

Through careful research and judgement of the development trend of the glue filling industry, Second Intelligent believes that no matter from the perspective of market demand or technology, in-line vacuum glue potting machine has a wide range of application prospects.

For this reason, Second Intelligent upgraded the original offline vacuum glue potting machine to achieve the process of automatic entry of the product into the vacuum box, automatic sensing of the positioning of the fixture in place, automatic closing of the door of the vacuum box, automatic vacuum pumping, and automatic potting of the glue according to the gluing procedure, and automatic pressure relief after the completion of gluing, automatic opening of the door, and automatic flow of fixtures out of the process solution.

After the product is assembled in the front section, it can be automatically transported to the internal conveyor line of the vacuum dispenser for positioning through the front receiving table. The preparation unit needs to heat and stir the A/B glue, and defoam and prepare the material under the vacuum environment of -100KPA.

Second Intelligent in-line vacuum glue potting machine has obvious advantages of high performance, reliability and durability, streamlined design, able to adapt to a variety of specifications, and absolute advantages for products with complex internal structure, high bubble requirements, and slow glue penetration.

It adopts industrial control machine + Second Intelligent motion control card integrated with advanced algorithm and Second Intelligent self-developed glue filling software control, equipped with friendly operation software, easy to operate and improve production efficiency.

02.Committed to product and process optimisation

Second Intelligent In-line vacuum glue potting machine perfectly solves the modern user’s demand for quality gluing. It is not a pile of technology, but a multi-dimensional integration based on user experience.

Second Intelligent always practices the concept of total quality development, starting from the actual needs of users, and constantly optimises and improves product design, raw material management, process improvement, etc., and constantly advances and polishes multi-dimensionally to practice the original intention. The launch of In-line vacuum glue filling machine products, experienced countless trial and error, invested a lot of time and resources, overcome the complexity of the production process,devices and other technical problems, to a very high degree of craftsmanship for the user to bring the true meaning of the potting experience.

In-line Automated Vacuum Glue Potting System

During the research and development of In-line vacuum glue potting machine, Second Intelligent also faces other difficulties: first, how to achieve miniaturisation and convenience of the equipment while improving the performance? Secondly, how to effectively remove the air bubbles in the glue?

Third, the choice of materials and components, how to ensure compatibility? Fourth, in terms of operability and safety, how to design user-friendly operation software? Fifth, how to improve the performance of the equipment and solve special needs through technological innovation?

In order to solve the above difficulties and problems, Second Intelligent has set up a strong R&D team for the two-component dispensing product line, established and maintained a close partnership, and made technical adjustments and improvements through repeated testing and verification. Benefiting from the long-term cooperation with the industry’s top customers, Second Intelligent is the first time to know the innovative application needs of industry enterprises and the direction of cutting-edge exploration.

In the process of meeting customer needs to promote the upstream and downstream linkage research and development, testing, practice, in the actual application of the scene repeatedly demonstrated in-line vacuum glue potting machine, to promote the in-line vacuum glue potting machine to the ground, and constantly iterative updating, the formation of a virtuous cycle, so as to always walk in the forefront of product innovation.

With the support of technology, Second Intelligent constantly upgrade the filling process technology, accelerate the development of products to intelligent, quality.

Thousands of hammers and refinements, keep improving. Second Intelligent not only adhere to the development of technological innovation of the two-component potting product line, but also to further explore the depth of the three-stage vacuum potting machine research and development, to provide equipment for the IGBT industry.

It provides equipment solutions for IGBT industry. In terms of function upgrading, Second Intelligent realizes real-time monitoring of the dynamics of the product to be filled to ensure the accuracy and quality of the filling, and achieves the filling process of vibration while filling, while accelerating the rapid penetration of glue and the discharge of air bubbles to effectively improve efficiency.

In terms of operation optimisation, Second Intelligent ensures the solidity and reliability of the in-line vacuum glue potting machine system through user-friendly operation software, which makes the operation more convenient and easy to start.

Outstanding performance, leading edge, can meet the needs of more areas of application.

In addition to the traditional 3C, semiconductor and other fields, Second Intelligent will further expand the in-line vacuum glue potting machine to automotive electronics, lithium batteries, hydrogen energy, biomedical, aerospace and other fields.