PCB Moisture-Curable Elastic Adhesive Dispensing for Waterproof & Anti-Static Protection | Second Intelligent

In the electronics industry, ensuring the long-term reliability of PCB assemblies requires more than soldering quality—it also depends on waterproofing, moisture protection, vibration resistance, and anti-static insulation.

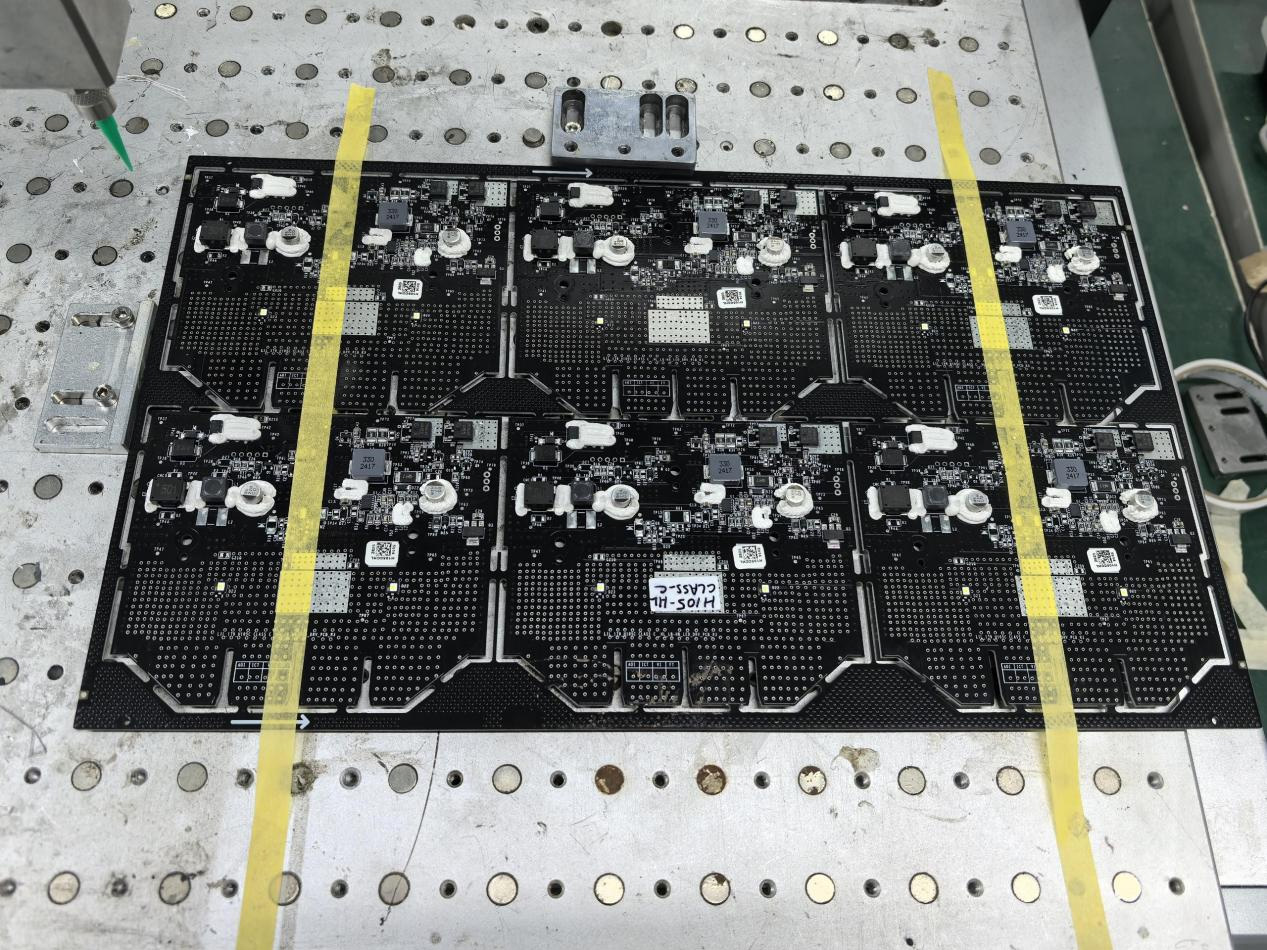

A client approached Second Intelligent seeking a fully automated solution to dispense Single-Component, Moisture-Curable, Elastic Adhesive (White) on their PCB boards to enhance environmental protection and component robustness.

Their adhesive was supplied in a 310ml cartridge, commonly used for RTV-type moisture-curing elastomers with medium-to-high viscosity.

1.Customer Background & Requirements

The client manufactures LED lighting modules and electronic control boards. Their PCB contains multiple sensitive components—LEDs, sensors, ICs, connectors—and requires precise bead and dot dispensing to achieve full protective coverage.

Customer Pain Points

Components closely spaced → manual dispensing machine easily contaminates solder pads

Moisture-curable elastic adhesive → medium/high viscosity, difficult to control manually

Needs uniform glue coverage for waterproofing and anti-static protection

Inconsistent manual output → unstable product quality, high rework rate

Large production volume → efficiency too low with hand dispensing

Adhesive Specification

Type: Single-Component, Moisture-Curable, Elastic Adhesive (White)

Features: Waterproof, moisture-proof, anti-static, vibration-resistant

Packaging: 310ml cartridge

Curing: Room-temperature moisture curing

Function: Environmental sealing + mechanical reinforcement

Typical Application Areas

● LED lamp bead waterproof sealing

● IC and sensor edge sealing

● Component foot reinforcement and insulation

● Moisture barrier for exposed solder joints

● Anti-static isolation coating in sensitive areas

2. Second Intelligent’s Customized Dispensing Solution

Based on the adhesive type and PCB structure, Second Intelligent designed a professional solution tailored for waterproofing & moisture-curable adhesive dispensing machine.

2.Process Engineering

The customer’s dispensing requirements were focused on waterproof integrity + insulation + consistent glue height, so our engineers created a dedicated process plan.

✔ Step 1: Custom Positioning Fixture

Ensures perfect alignment for every PCB panel.

✔ Step 2: Sealing/Bead Path Programming

Engineers programmed:

Waterproof perimeter beads

Component-edge sealing

Dot reinforcement on critical components

Tight-curve trajectory for irregular boards

✔ Step 3: Flow Control Matching Adhesive Behavior

Moisture-curable elastic adhesive has high thixotropy—our engineers calibrated:

Pressure

Rotation speed

Needle height to ensure smooth bead formation.

✔ Step 4: First-Article Verification

Adjusting bead width, thickness, and curing behavior.

✔ Step 5: Full Production Run

Stable output day after day.

Overall result: improved environmental protection + higher reliability + lower production cost.

5.Why Customers Trust Second Intelligent

① Deep Expertise in Moisture-Curable & Elastic Adhesive Dispensing

We understand the flow behavior, curing characteristics, and valve compatibility of RTV & elastic sealants.

② Precision Control for Waterproof Sealing Applications

We specialize in:

Perimeter waterproof beads

IC sealing

Component reinforcement

Moisture barrier dispensing

③ One-Stop Service

From fixture design → path programming → sample testing → mass-production tuning.

④ Trusted by Global Electronics Manufacturers

LED, automotive electronics, sensors, smart appliances, energy systems.

6.Suitable Application Industries

This solution is ideal for:

Automotive lighting modules

Sensor modules

Consumer electronics

PCB control boards

Smart home devices

Medical electronics

Waterproof LED and optical modules

7.Need Waterproof, Moisture-Cure Adhesive Dispensing?

We can provide:

✔ Free sample testing

✔ Adhesive dispensing process development

✔ Full equipment configuration

✔ 310ml cartridge dispensing solution

✔ Waterproof sealing process consultation

Contact our engineering team for a customized proposal.