India’s industrial water purification market is experiencing explosive growth. The market size reached $$2.73 billion in 2025 and is projected to surge to$$4.35 billion by 2030, with a compound annual growth rate (CAGR) of as high as 9.71%. However, water scarcity and pollution issues continue to restrict industrial development — the national per capita freshwater availability has dropped below 1,500 cubic meters. Industrial wastewater discharge and untreated domestic sewage have caused pollution to most surface water bodies. Moreover, the Zero Liquid Discharge (ZLD) regulations that “Red Category” industries must comply with have further driven up the demand for high-efficiency water purification equipment.

Shenzhen Second Intelligent Equipment Co., Ltd. focuses on the core demands of India’s industrial scenarios and launches a full-process intelligent equipment portfolio, including industrial RO membrane cutting machines, industrial negative pressure testing machines, and fiberglass winding machines. With precise, efficient, and stable industrial-grade solutions, the company helps India’s chemical, oil and gas, food and beverage, metallurgy, and other industries break through water purification bottlenecks, achieving compliant production and green upgrading.

(1) Targeting India’s Industrial Pain Points: Tailored Solutions of Second Intelligent RO Equipment

India’s industrial water purification sector faces multiple challenges: insufficient wastewater treatment capacity (major cities can only treat 30% of sewage), shortage of professional technical talents, the need for equipment to adapt to high-temperature and high-humidity working conditions, and strict import compliance requirements. Second Intelligent RO Equipment addresses these challenges with localized adaptation advantages:

● Adapting to diverse industrial scenarios: Covering mainstream industrial RO membrane element specifications with diameters ranging from 100–210mm and lengths from 800–1100mm, it perfectly matches industrial water purification systems in chemical, pharmaceutical, electronics, metallurgy, and other industries. Compatible with commonly used models such as 4040 and 8040, it meets the production needs of enterprises of all scales.

● Meeting Compliance and Efficiency Requirements: The equipment performance is fully compatible with India’s production capacity, facilitating enterprises to easily obtain production licenses. The negative pressure testing machine achieves a capacity of 750 units within 8 hours, while the fiberglass winding machine has an hourly capacity of 25 units. This significantly improves the production efficiency of industrial membrane elements and alleviates local production capacity pressure.

● Adapting to local industrial environments: Supporting AC220V 50Hz/60Hz power supply and 0.4–0.7MPa air source requirements, it is compatible with India’s conventional industrial configurations. The sheet metal frame and cold-rolled plate material ensure durability, enabling adaptation to high-temperature and high-humidity working conditions. Its compact structure and small footprint make it suitable for various industrial workshop layouts.

● Reducing operation and management costs: The automated design reduces reliance on skilled workers. The PLC control system features user-friendly operation, requiring no complex training to get started. This effectively mitigates the talent shortage in India’s industrial sector while lowering human error rates and management costs.

(2) Core Equipment Matrix: Consolidating the Quality Foundation of India’s Industrial RO Membrane Elements

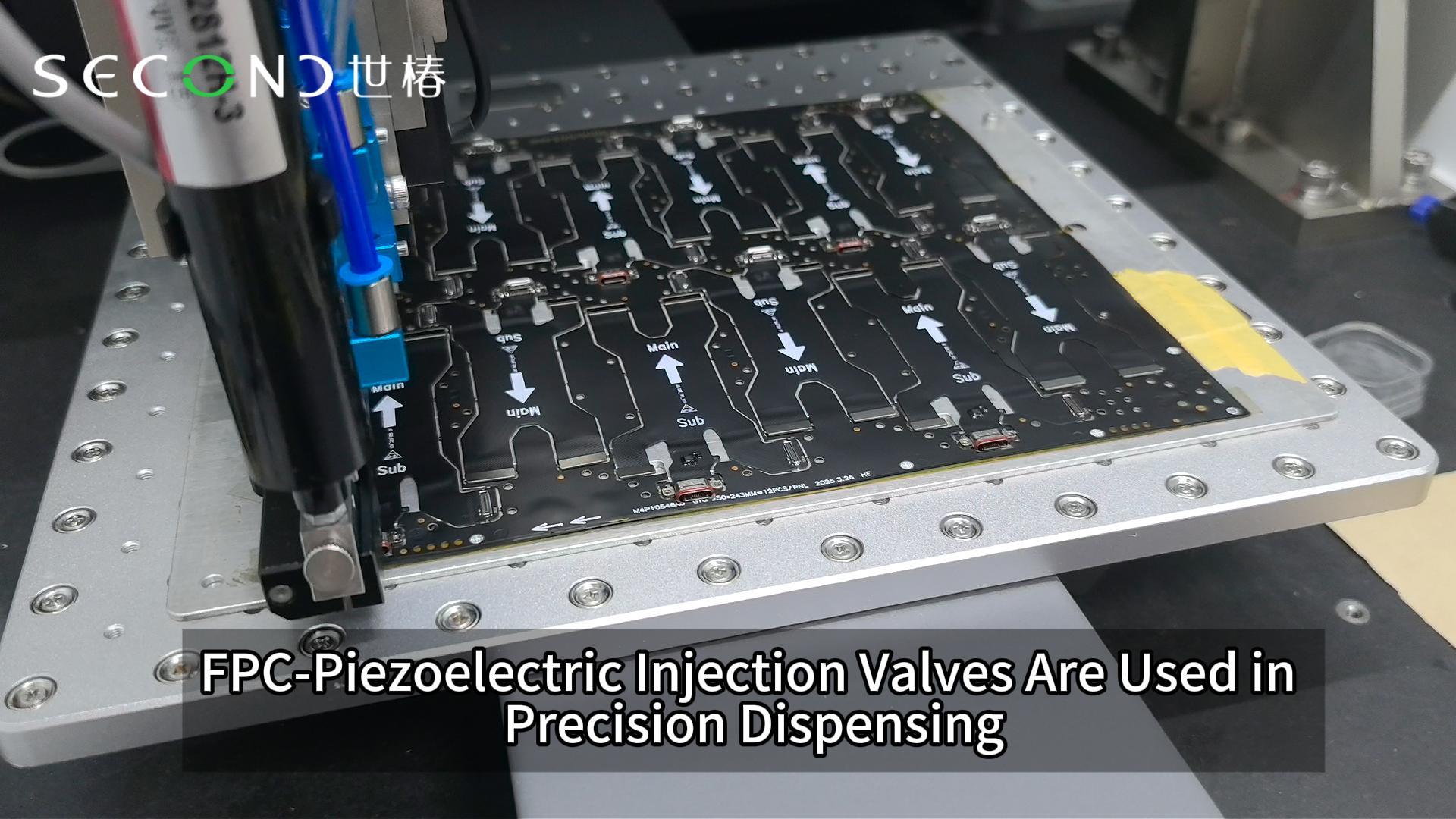

Second Intelligent’s industrial RO equipment series covers the entire process of membrane element trimming, testing, and protection. With industrial-grade precision and stability, it provides core equipment support for India’s industrial water purification:

1) Industrial RO Membrane Cutting Machine (SEC-S8040-WT): Industrial-Grade Precision Cutting with High Efficiency and Stability

● Designed specifically for large-scale production of industrial RO membrane elements, it adopts two independent left-right blade sets and a bidirectional moving mechanism, combined with a rotating motor to drive the uniform rotation of elements, achieving consistent edge trimming and ensuring industrial-grade dimensional accuracy. The left positioning station uses dual fixation of a positioning cylinder and a tensioning cylinder to prevent element displacement during cutting, with cutting precision far exceeding manual operations.

● In terms of operation, it is equipped with a PLC + touch screen control system, allowing flexible setting of parameters such as cutting position and speed. A single operator can complete the entire process of loading, unloading, and cutting. The whole machine is fitted with a protective cover to realize man-machine separation operation, complying with international industrial safety standards. Meanwhile, the screw drive mode and adjustable speed design (0–72rpm) can adapt to the edge trimming process requirements of different industrial membrane elements, ensuring stable and reliable operation and reducing the risk of downtime due to faults.

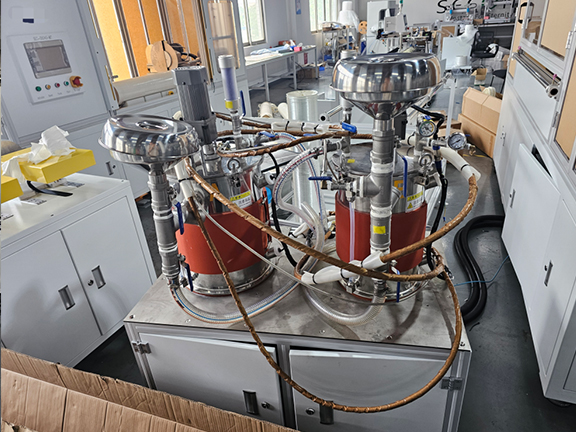

2) Industrial Negative Pressure Testing Machine (SEC-S8040-WU): Precise Quality Control and Compliance Assurance

● As a key testing equipment for industrial membrane elements before factory delivery, it is designed to meet India’s stringent industrial quality requirements, adopting a fully automated process of “vacuum extraction – pressure holding – automatic judgment”. During testing, the module automatically inserts the RO membrane roll; after vacuum extraction to the set value, it enters the pressure-holding phase (holding time can be freely set). If the pressure remains stable during holding, a green light indicates pass; otherwise, a red light alerts for failure. This intuitively and accurately screens out unqualified products, avoiding negative impacts on the operation of industrial water purification systems caused by substandard membrane elements.

● The equipment adopts a “one-drive-two” vacuum extraction design, paired with Taiguan vacuum pumps, Second Intelligent air tanks, and SMC vacuum gauges, ensuring strong airtightness and stable vacuum pressure with testing precision far superior to manual methods. It supports parameterized setting of production quantity, automatically stopping and alarming after reaching the set output, facilitating production management. With a capacity of 750 units per 8 hours, it perfectly matches the rhythm of large-scale industrial production. Core components are selected from well-known brands such as AirTAC solenoid valves. The equipment has a power of 4.5KW and is easy to maintain, meeting the demand for cost-effective industrial equipment in India.

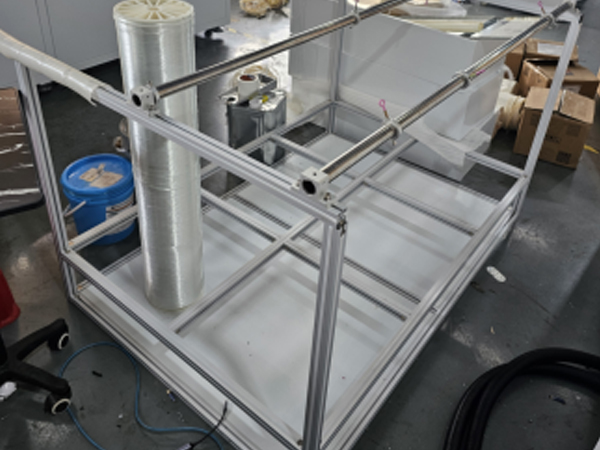

3) Fiberglass Winding Machine (SEC-S8040-WE): Enhanced Protection and Extended Industrial Service Life

● In response to the high concentration of heavy metals and pollutants in India’s industrial sewage, fiberglass winding is adopted to enhance the strength and corrosion resistance of membrane element shells, extending the service life of industrial water purification systems. The equipment operates in a semi-automatic mode: after manual feeding, it automatically completes lifting, positioning, clamping, winding, and other processes. The winding precision reaches ±0.25mm, ensuring a uniform and firm protective layer that effectively resists the erosion of industrial wastewater.

● Equipped with Second Intelligent’s independently developed metering system and dual-liquid dynamic valve, gear pump glue supply ensures uniform glue discharge, and dynamic mixing tubes guarantee full mixing of AB glue. The suck-back design prevents glue dripping and leakage, and the six-channel glue-passing module removes excess glue from fiberglass, saving consumable costs. Core drives are selected from Panasonic servo motors and Leadshine stepper motors, ensuring precise and stable operation. The winding time per unit is only 141 seconds, with a capacity of 25 units per hour, meeting the needs of medium-to-large-scale industrial production. Additionally, the equipment supports AC220V 50Hz/60Hz power supply, complying with India’s industrial power standards.

(1) Empowering India’s Industry: Core Competitiveness and Cooperation Value of Second Intelligent

Against the backdrop of the Indian government’s promotion of policies such as “Swachh Bharat” and AMRUT 2.0, as well as industrial enterprises’ pursuit of “water positivity” goals, Second Intelligent industrial RO equipment has become the preferred cooperative choice for enterprises with four core advantages:

● Mature and reliable technology: With years of experience in providing integrated fluid application solutions, core components are sourced from internationally renowned brands. The equipment features low failure rates and easy maintenance, meeting India’s demand for high-stability industrial equipment and reducing long-term operation costs.

● Full-process solutions: Covering the entire process of industrial RO membrane element trimming, testing, and protection, it eliminates the need for third-party equipment, providing Indian industrial enterprises with one-stop equipment support and simplifying procurement and integration processes.

● Strong compliance adaptability: The equipment design complies with international industrial safety standards, facilitating smooth customs clearance and market entry for enterprises.

● Customized service support: Offering full-cycle services from equipment selection and parameter debugging to after-sales maintenance, it can customize solutions according to the industrial scenarios and capacity needs of Indian enterprises, helping them achieve rapid production and efficiency gains.

The rapid expansion of India’s industry relies on stable and compliant water purification systems, and high-quality RO membrane elements are the core guarantee for industrial water purification efficiency. With its core advantages of precision, efficiency, and stability, Second Intelligent industrial RO equipment provides full-process solutions from membrane element processing to quality testing for India’s chemical, oil and gas, food and beverage, and other industries. It not only helps enterprises improve production efficiency and reduce operation costs but also lays a solid foundation for industrial sustainable development in terms of water purification. In the future, Second Intelligent will continue to deepen localized adaptation for the Indian market, focus on technological innovation in the industrial water purification field, and work hand in hand with Indian enterprises to co-write a new chapter of industrial green development in this promising market.

[contact-form-7 id=”5″ title=”Contact form 1″]