What factors affect the working efficiency of two-component glue potting machine?

The working efficiency of the two-component glue potting machine is affected by many factors. The following are key factors and optimization suggestions:

1.Equipment parameter setting

● Air pressure stability:

Insufficient air pressure will lead to slow glue dispensing speed or unstable flow rate (such as the recommended pressure range is not up to standard), and the pressure regulating valve and air compressor performance need to be checked.

Excessive air pressure may cause bubbles or glue waste, and it needs to be adjusted to a reasonable range according to the viscosity of the glue (such as instant glue is recommended to be 60-80psi).

● Proportional pump calibration:

Incorrect AB glue ratio (such as 10:1 is mistakenly set to 5:1) will cause uneven mixing or poor curing, and the proportional pump needs to be calibrated regularly.

Clogged or worn mixers will reduce the mixing efficiency and need to be cleaned or replaced in time.

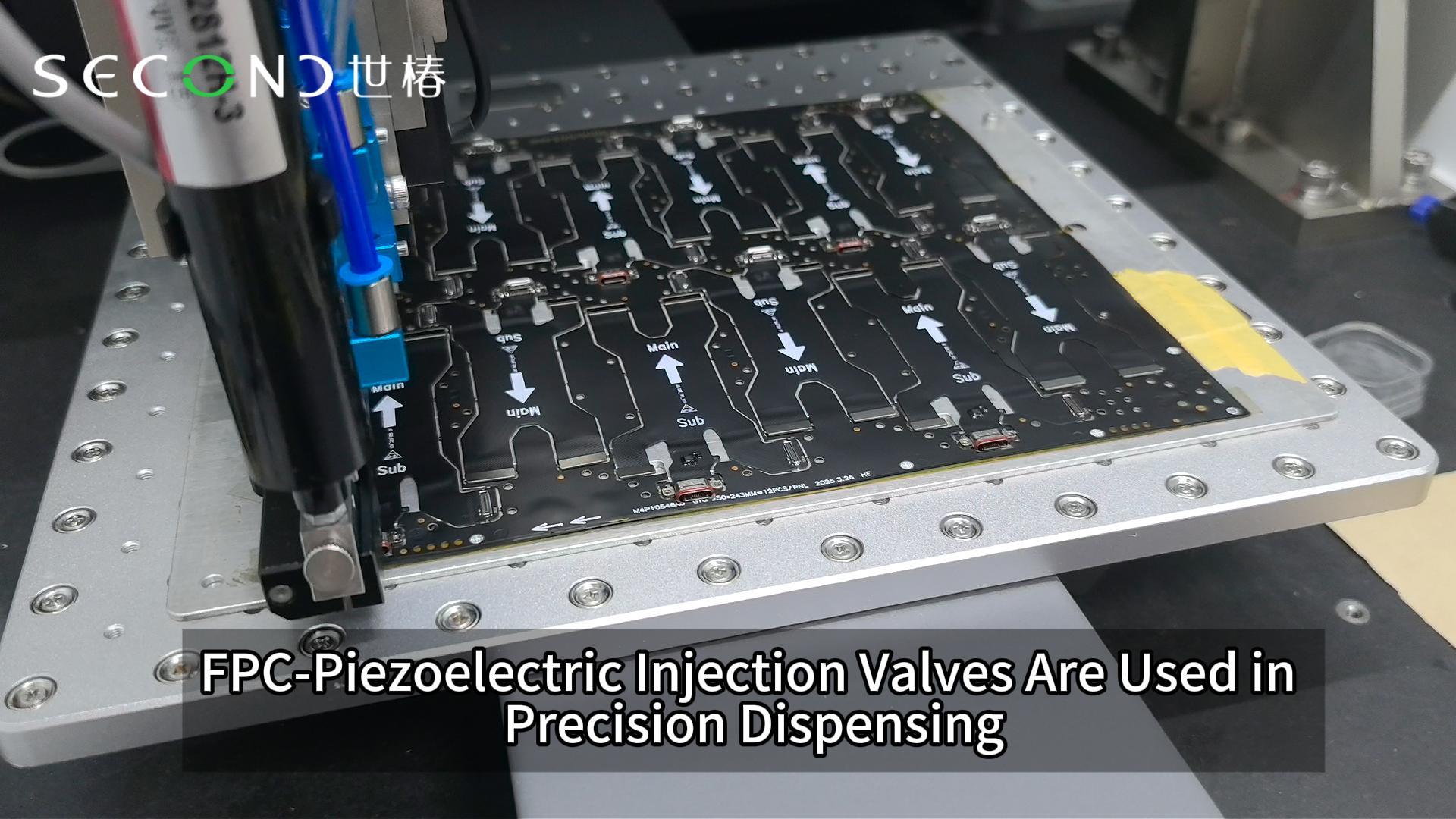

Automatic two-component glue potting machine SEC-S3030-C

● Second Intelligent’s unique motion controller plus advanced algorithms, combined with high-precision three-axis manipulators, achieve three-dimensional high-speed and precise motion

● Through precise control of the metering motor, the two-component glue can be accurately proportioned, automatically mixed, and automatically quantitatively discharged

● With vacuum feeding and vacuum degassing, optional heating, stirring, automatic cleaning, pressure monitoring and other functions, it can cope with various complex glue environments

● The operating system is stable, the operating interface is friendly, and the cost performance is high!

2.Glue characteristics

● Viscosity and fluidity:

High-viscosity glue (such as silicone, epoxy resin) requires higher pressure and larger-diameter pipelines, otherwise the glue dispensing speed will be slow.

Low-viscosity glue (such as instant glue) is prone to blockage of pipelines due to moisture crystallization, and needs to be sealed and stored and preheated.

● Bubble problem:

If the glue is not fully stirred or there is moisture on the surface of the workpiece, bubbles will occur, affecting the speed and quality of glue filling, and vacuuming or preheating the workpiece is required.

3.Pipeline and glue supply system

● Pipeline design:

Pipes that are too thin (such as less than 1/4”), too many bends or too long will increase resistance and cause delayed glue discharge.

It is recommended to use large-diameter straight pipes and reduce joints, especially for high-viscosity glue.

● Blockage risk:

Instant glue, anaerobic glue, etc. are prone to agglomeration due to moisture or repeated use, and the pipelines need to be cleaned with acetone regularly.

The cleanliness of the mixing tube or static mixer directly affects the smoothness of glue discharge.

Two component glue dispensing potting machine SEC-S8700-E

Second Intelligent AB glue potting machine SEC-S8700-E is a two-component glue potting machine, which is compact and functional, flexible in manual operation, and Super cost-effective. The metering motor of this equipment is precisely controlled by PLC to achieve accurate proportioning, automatic mixing, and automatic quantitative dispensing of two-component glue. It has functions such as vacuum feeding, vacuum degassing, heating, stirring, and automatic cleaning, and can cope with various complex gluing environments; it adopts a unique industrial design, with a generous appearance, compact structure, stable operating system, friendly operating interface, and high cost-effective.

4.Operating environment

● Temperature and humidity:

Low temperature will cause poor fluidity of the glue, and it needs to be preheated to the recommended temperature (such as above 25°C).

High humidity environment is prone to crystallization of instant glue, and humidity needs to be controlled and desiccant used.

● Workpiece preparation:

If there are bubbles on the surface of the workpiece or the gaps are not filled, the glue filling time needs to be extended or the glue amount needs to be adjusted.

5.Maintenance and consumables

● Equipment aging:

Problems such as wear of the glue valve seal ring and leakage of the proportional pump will reduce efficiency, and consumables need to be replaced regularly.

● Mixer status:

Static mixing tube blockage or dynamic agitator failure will lead to uneven mixing, which needs to be cleaned or replaced in time.

6.Process parameters

● Glue filling speed and path:

When operated manually, too slow glue filling speed or unreasonable path planning will extend the cycle time, and automated equipment can improve efficiency.

● Curing time:

Slow glue curing speed (such as room temperature curing type) will take up equipment time, and quick-drying glue can be heated or replaced.

Optimization suggestions

● Equipment level: Regularly calibrate the proportional pump, check the air pressure system, and replace aging seals and mixing tubes.

● Process level: Adjust the pipeline diameter, pressure and temperature according to the characteristics of the glue, and pre-treat the workpiece to reduce bubbles.

● Operation level: Train operators to use the equipment in a standardized manner to avoid blockage or imbalance of proportions due to misoperation.

By comprehensively optimizing the above factors, the working efficiency of the two-component glue potting machine can be significantly improved and the failure rate can be reduced.

Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component automated potting machines and coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.

[contact-form-7 id=”5″ title=”Contact form 1″]