Copyright © 2025 Shenzhen Second Intelligent Equipment Co., Ltd All rights reserved.

High scalability, high compatibility, suitable for screw stack production – SEC – Stacking machine system – Screw-type

The goal of designing the screw stacking line is to develop a fully automatic assembly line for the stacking and assembly of PEM hydrogen fuel cell screw stacks. The loading and unloading of wire/cable and materials is achieved by robots. The stacking of stack end plates, current-collector plates, bipolar plates and other materials is completed by robots. The high-precision servo pressing system to ensures the precise pressure of the stack, the CCD visual alignment system ensures the accuracy, the studs are manually locked, and the multi-directional air tightness test of the stack is carried out by the flow method accurately.

High scalability, high compatibility, suitable for strapping stack production – SEC– FC battery stacking system – Strap-type

The goal of designing strap-type stacking line is to develop a fully automatic assembly production line for stacking, assembling, and fastening of stacked battery cells. The stacking of current-collector plates, bipolar plates, and other materials is completed by robots. The high-precision servo pressing system is applied to ensure the precise pressure during the stack, the AI visual alignment system ensures the accuracy, the straps are automatically welded, and the stack is airtight tested in multiple directions by the flow method.

SEC – Fuel cell stacking system – Multi purposes

High scalability, high compatibility meet various production needs in different stages.

The design of the system stacking line aims to develop a fully automatic assembly line for stacking and assembling PEM hydrogen fuel cell battery stacks. The loading and unloading of materials in this line is realized by robots, stack end plates, current collector plates, bipolar plates, etc. The stacking of materials is completed by the robot, the high-precision servo press ensures the precise pressure of the stack, the visual alignment system ensures the accuracy, the stack is automatically tightened, and the multi-directional air tightness test is performed on the stack by the flow method.

Fully automatic MEA package line, from rolls to packaged product – SEC-H500-ML

Fully automatic hydrogen fuel cell MEA packaging system, from raw material rolls to complete tested product.

MEA Seven-in-one automatic packaging line – SEC-H500-7M

Realize hydrogen fuel cell GDL+5CCM+GDL dispensing, laminating and pressing

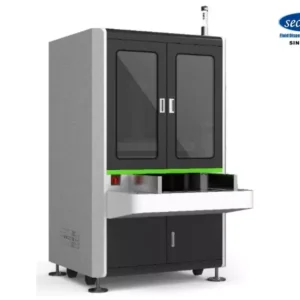

Air tightness testing machine (compatible with bipolar plate, and MEA air tightness testing need, multi-purposes) – SEC-H500-AT

This is multi-purposes machine, it can realize the air tightness detection of hydrogen fuel cell bipolar plate, MEA monolithic, and multi-sheet/layers of air-tightness test.