Introduction:

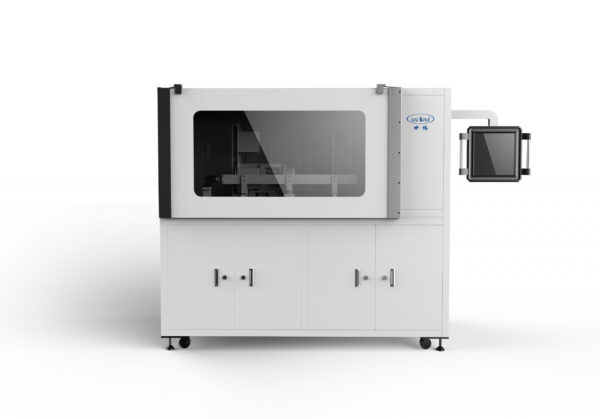

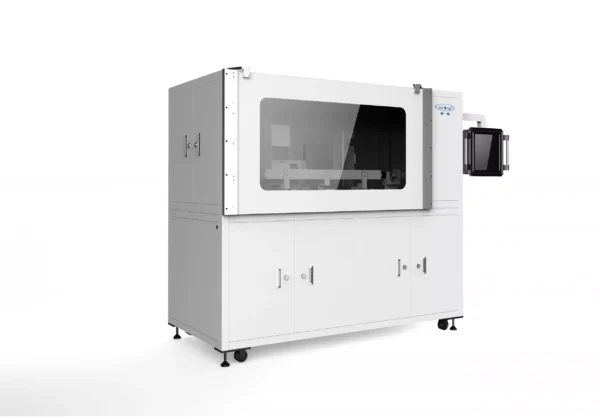

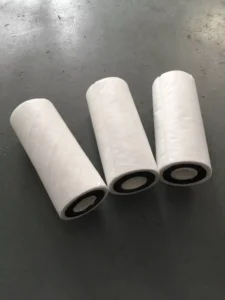

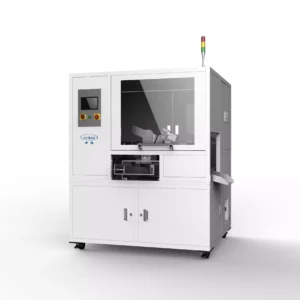

The equipment is suitable for slitting different sizes of carbon block fiber rods. User friendly design for efficient, and effective operation.

How it works?

Operated by one person, The equipment can complete the slitting of the entire rolled carbon block automatically. Operator manually put the completed carbon block on the machine, set up, or load the preset parameters. After it completed cut, operator manually unloads the completed blocks and replace a new one. For each new setup, the cutting length can be set and stored via the touch screen. Equipment is really user-friendly, safe, reliable, and high efficiency. The moving parts are covered with safety cover and safety light curtain.

MANUFACTURING:

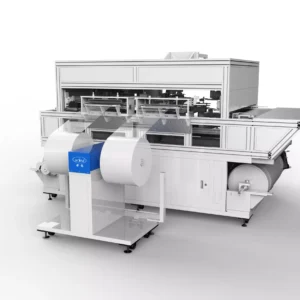

This is RO and water filter fabricating machines and equipment production floor. From the house to industrial types of RO, they were produce in this department.

The machine is effective and efficient for different type of element withing the ranges.

Application:

Operated by one person, The equipment can complete the slitting of the entire rolled carbon block automatically. Operator manually put the completed carbon block on the machine, set up, or load the preset parameters. After it completed cut, operator manually unloads the completed blocks and replace a new one. For each new setup, the cutting length can be set and stored via the touch screen. Equipment is really user-friendly, safe, reliable, and high efficiency. The moving parts are covered with safety cover and safety light curtain.