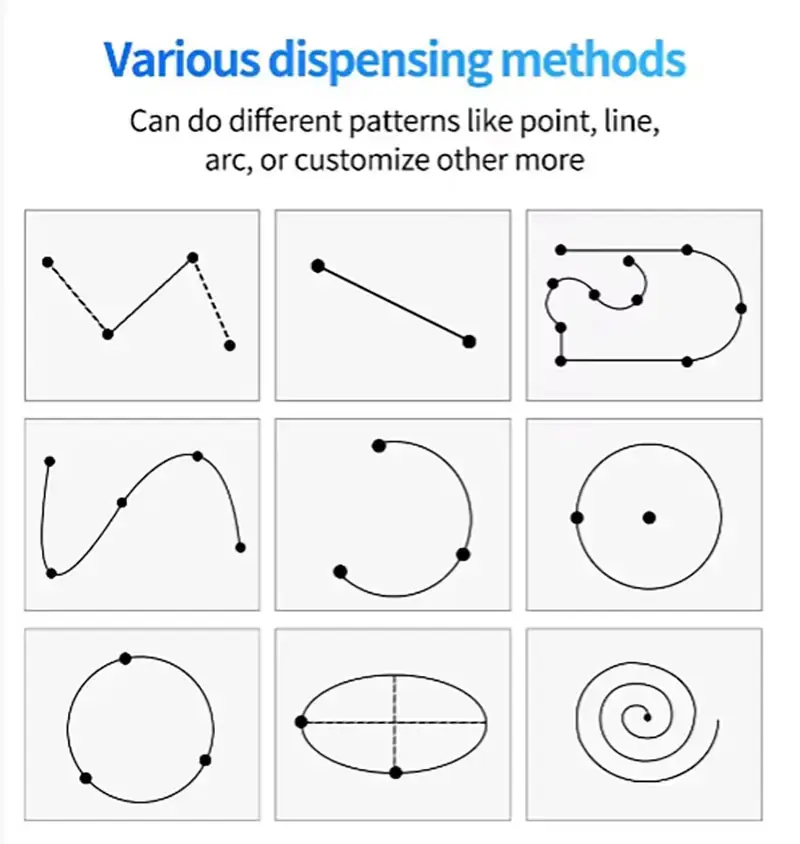

Automated high viscosity thermal interface material deispensing machine, Second’s unique control software can follow the set points, lines, circles, arcs and other trajectories

Feature:

- Unique control software

- With vacuum feeding, vacuum deaeration, stirring

- Heating, automatic cleaning

PRODUCT DETAILS

Supporting Systems

- Compared with the traditional two-component glue filling machine, this equipment is suitable for the automatic mixing and automatic mixing of the three-component glue, and it has the functions of vacuum feeding, vacuum defoaming, stirring, heating and automatic cleaning.

- The operation issimple, which greatly saves the manual mixing time, improves efficiency, saves costs, and has a high cost performance!

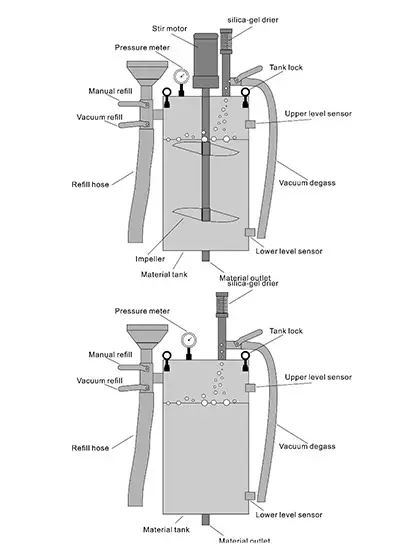

Material Tanks

- In order to achieve the highest stability and accuracy, the material tank of the machine is well-sealed

- With locking devices and valves, and each machine is equipped with material tanks of different capacities

MANUFACTURING

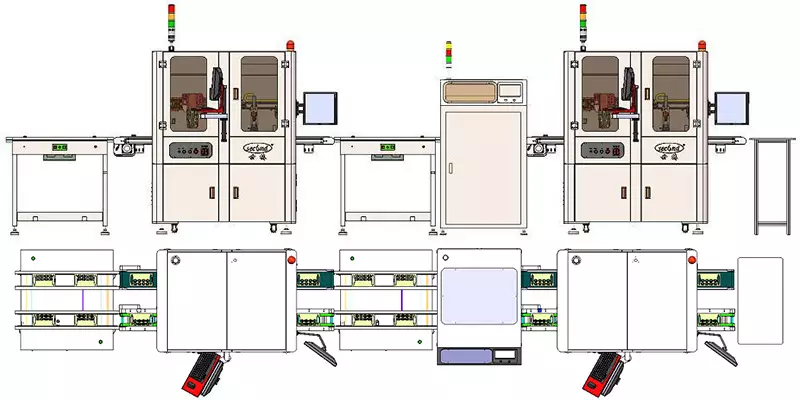

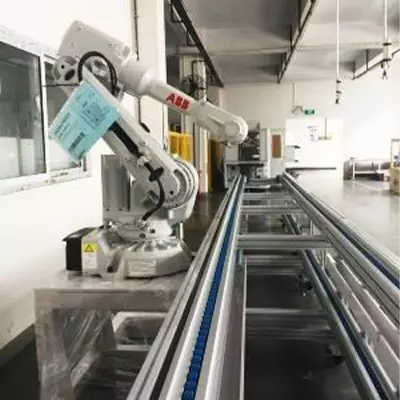

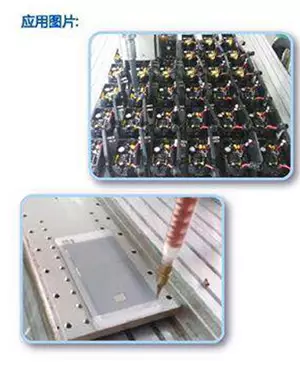

Salcomp – 2 sides glue dispensing, curing, belt reflux automated production

How It Works

CASE

Compared with the traditional two-component glue filling machine, this equipment is suitable for the automatic mixing and automatic mixing of the three-component glue, and it has the functions of vacuum feeding, vacuum defoaming, stirring, heating and automatic cleaning.

Dispensing process:

Multi-valve picture display

Advantages

- Simple operation

- Greatly saves the manual mixing time

- Improves efficiency

- Saves costs and cost-effective

Industry Applications:

SOLUTION

Project

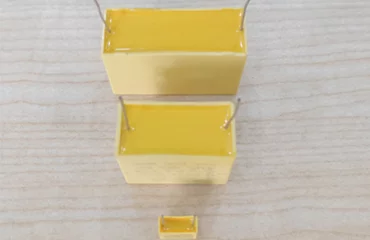

The LED Drive Power, Machine SEC-3030C

Project Background

The LED drive power supply is a power converter that converts the power supply into a specific voltage and current to drive the LED to emit light. The Shichun glue potting equipment is used in the LED drive power supply to play a role in heat dissipation, moisture proof, waterproof, and flame retardant.

Project Features

Heat dissipation, moisture proof, waterproof, flame retardant

Project Advantages

1. Three-axis linkage, capable of making arbitrary points, lines, arcs, circles, three dimensions, etc.;

2. Dynamic mixing, uniform mixing, no dripping;

3. Nano ceramic screw pump, good wear resistance;

4. 12CC screw pump, fast glue output speed, 30g/sec;

5. It has the function of pump pressure detection to ensure quality and safe production;

6. It has dynamic fault detection function to ensure quality and safe production;

7. Optional large-capacity storage barrel, saving feeding time and improving efficiency;

8. Online glue filling, without manual operation, automatic connection operation.

-300x300.webp)