Feature:

- Latest easily operated, user-friendly teaching pendant

- Can store up to 999 dispensing files

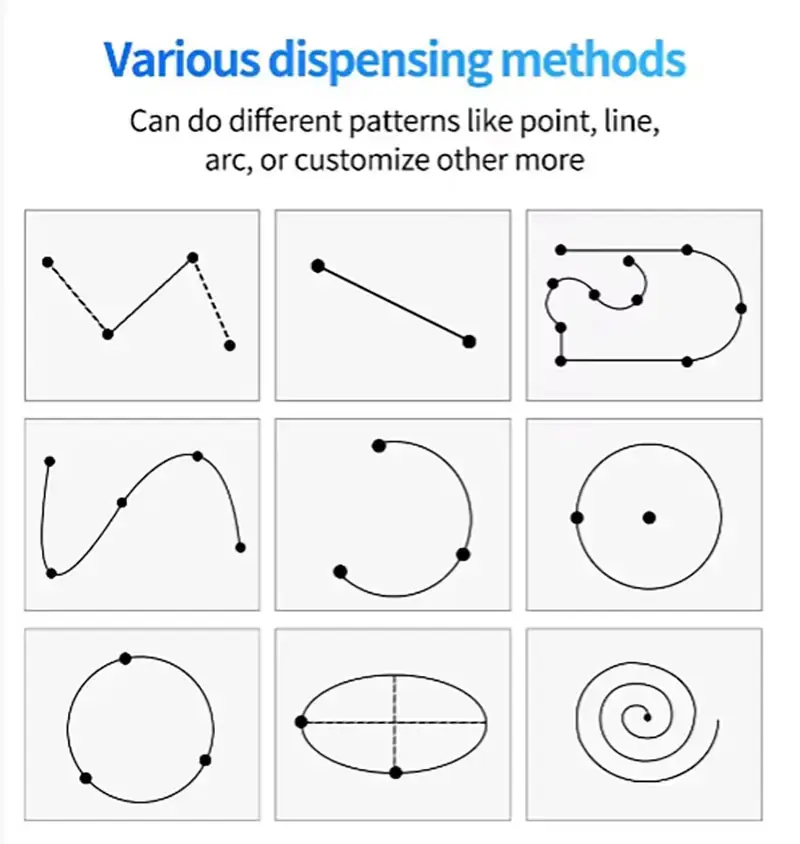

- Achieve 3-dimensional dispensing trajectory

- Durable one-piece aluminum die-cast machine body

- High dispensing and transporting accuracy

PRODUCT DETAILS

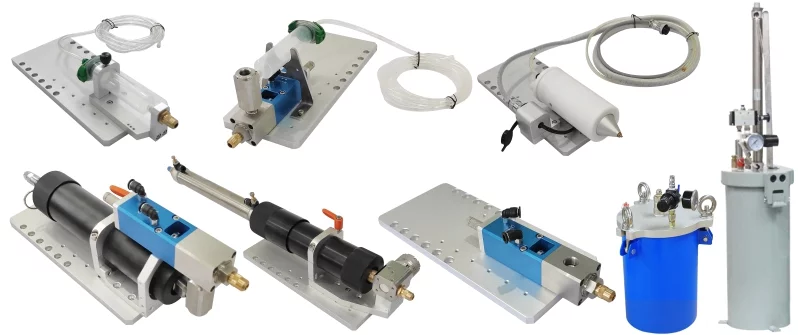

Dispensing valve

This dispensing valve is direct made by Second with quality. The materials are high quality aluminum and stainless steel, great for anti corrosion, precise and durable. It is also low maintenance with only O-ring and sealant need to be replaced one retired. Different valves also equip with suck-back function, effectively prevent dripping. It is pairing with the high quality dispensing controller for precise dispense results.

MANUFACTURING

In the department, it builds various types of dispensing valves, and controlers, and and of course the desktop dispensing robots as well.

More and more products are applying bonding technique in their production. Especially in the EMS factories, they must have dispensing and potting equipment onsite. As the increasing demands for slimmer and lighter electronic gadgets, and wearable gears, many of the products are designed to be bonding, assembling, and or sealing by adhesive materials with automatic machines.

CASE

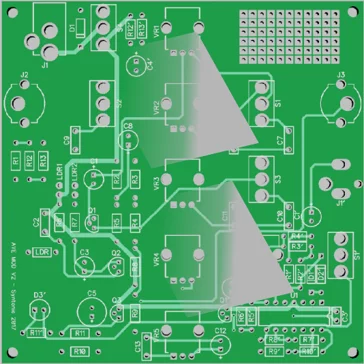

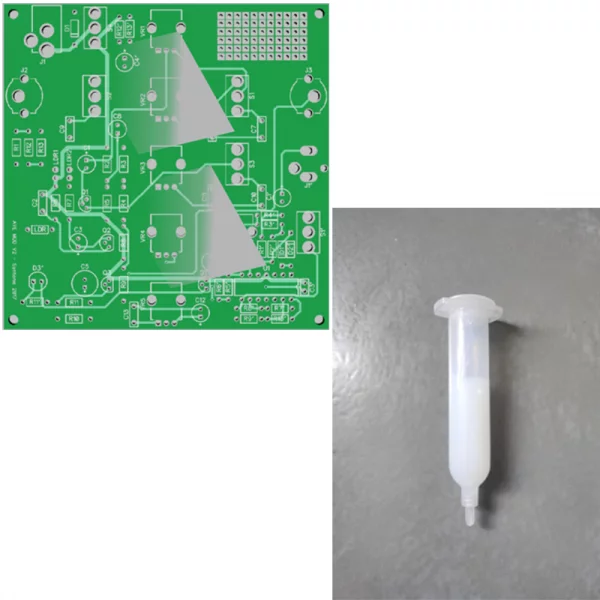

This is a popular 30cc syringe automatic glue dispenser, it equips with a flexible, and user-friendly filling system, allowing to use of 3cc to 50cc syringes sizes. Simply install the syringe on the mounting bracket, tighten up the lock, and connect the air-pressure controller, set dispensing trajectory, and parameter, you are ready to dispense. This is an E380 desktop dispenser, it is of good quality and with high dispensing precision, with its flexibility, it is most welcome in EMS factories for appl UV, red glue, solder paste, epoxy, and another adhesive on electronic PCB, chips, LCD screen, cellphone case, parts, and other components

Dispensing process:

Multi-valve picture display

Advantages

- Adaptable to different valves for different adhesives

- Compact body with a dispensing table (380mm area)

- Emergency stop button improves security

- Built for professional and heavy-duty use

- One-year’s warranty but lifetime service support

Applications

Used in the fixing and protection of PCB electronic parts in the electronics industry, bonding of mobile phone and notebook shells, LCD glass, LED dispensing, optical lens dispensing and packaging, automotive parts, hardware parts

Industry Applications:

-300x300.webp)