Introduction:

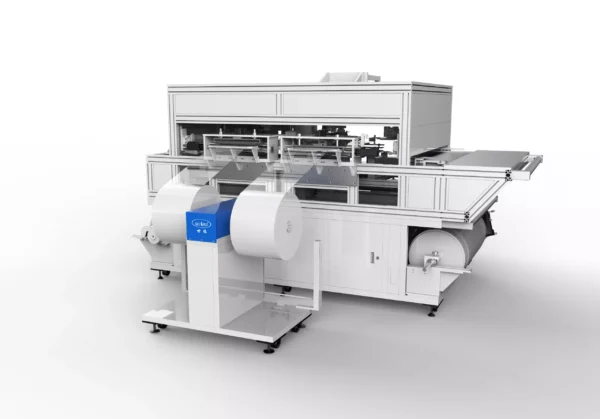

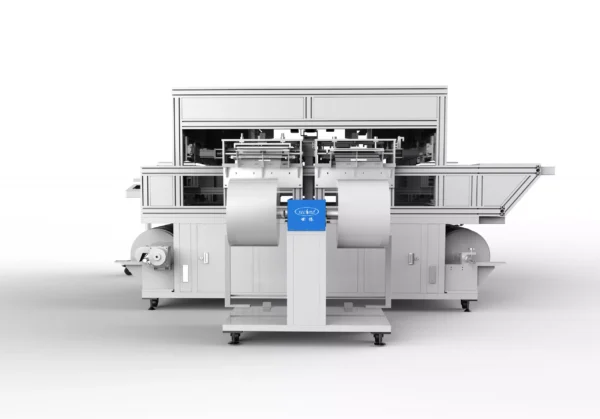

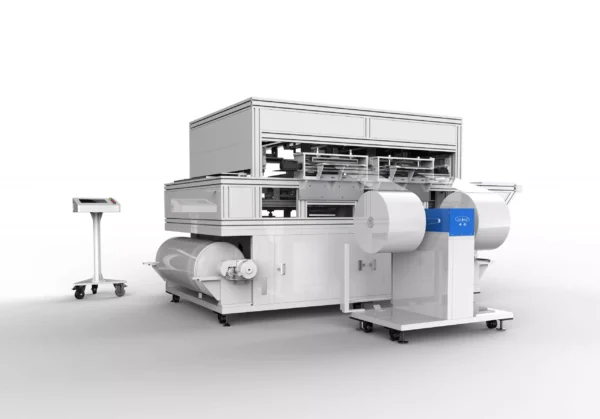

The equipment is suitable for the cross-cut folding, and stacking process of household RO cartridge leaf, tricot. It cuts the membrane horizontally for different type of prepping need.

How it works?

Operator only need to manually load the membrane and spacer (net) rolls on the machine, set the parameters, and the equipment will automatically run to complete the entire production just after one-key startup, the entire process is automatic without any intervention. The machine can use membrane with width 950-1200mm and 220-320mm (340mm size can be customized) spacer (net), automatic fixed-length cutting, automatic folding, and automatic blanking process. The length and position parameters can be set, the efficiency is high, the folding is neatly. With this machine 1 operator can watch multiple sets of equipment at the same time.

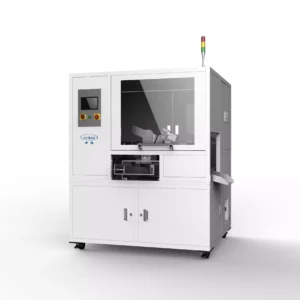

MANUFACTURING:

This is RO and water filter fabricating machines and equipment production floor. From the house to industrial types of RO, they were produce in this department.

The machine is effective and efficient for different type of element withing the ranges.

Application:

Operator only need to manually load the membrane and spacer (net) rolls on the machine, set the parameters, and the equipment will automatically run to complete the entire production just after one-key startup, the entire process is automatic without any intervention. The machine can use membrane with width 950-1200mm and 220-320mm (340mm size can be customized) spacer (net), automatic fixed-length cutting, automatic folding, and automatic blanking process. The length and position parameters can be set, the efficiency is high, the folding is neatly. With this machine 1 operator can watch multiple sets of equipment at the same time.