Features:

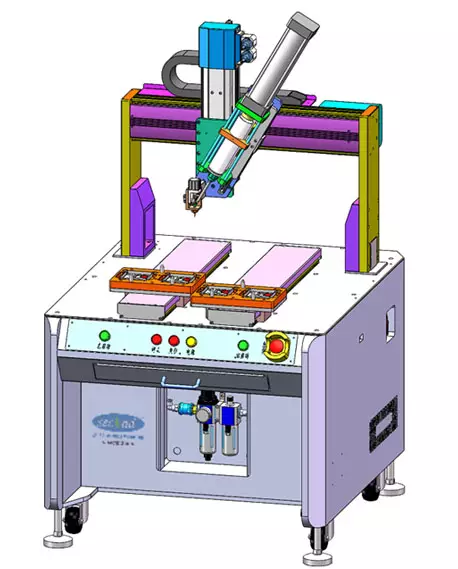

One-piece of square-steel stand for firm structure and stable operation.

lAble to adopt various dispensing units, realize multi-industry, multi-process dispensing application.

lStraightforward and convenient hand-held control system makes dispensing and operation more flexible.

lWith good-value performance, it can also meet most EMS dispensing application processes

lFlexible hand-held control system with table-top simple operation and floor-standing stability

Main configuration:

- Three/four axis base platform

- Handheld multi-axis dispensing control system

Machine option functions:

- Safety cover

- Auto nozzle alignment system

- Safety light-curtain

- Material-level detection sensor

Product feature:

Rich-product variety:

From entry-level to precision-level, from teaching pendant control system to industrial computer control system, from three-axis to six-axis dispensing applications, it meets the dispensing needs of multi-energy, multi-industry and multi-process.

Diversified application processes and modules:

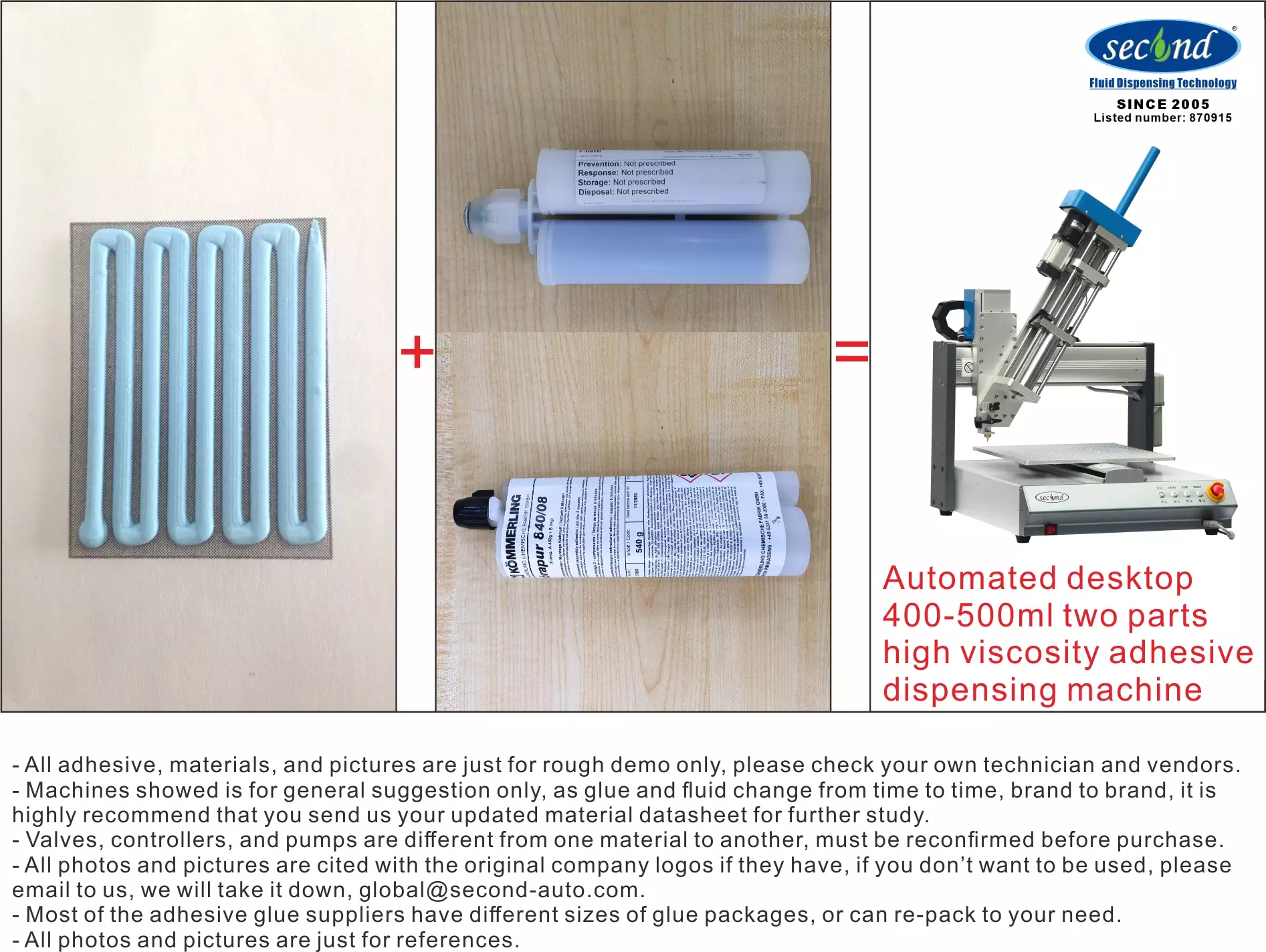

From 5ML to 200L packaging glue, from various needle rotary dispensing to various product rotary dispensing, from simple syringe dispensing to metering dispensing and non-contact jet dispensing.

Powerful system functions:

From three-axis applications to eight-axis applications, from simple automatic nozzle alignment to complex 3D scanning and path guidance.

Design concept:

Straightforward and user-friendly, emphasizing the unity and practicability of the design, the products are presented in a simple and practical way, while taking into account the design concept of ergonomics, making the operation of the equipment more user-friendly.

EC-series machine performance :

CCD visual programming for precise positioning, visual correction, to improve programming efficiency and dispensing accuracy;

English operating system, the software interface layout is clear, the operation is user-friendly, easy to learn and understand;

Support visual inspection, integrated control of dispensing and visual inspection, multi-purpose machine, effective control of dispensing yield;

Can be equipped with a line laser scanner for 3D path guidance and flexible dispensing;

The software can support a variety of dispensing systems and functional module applications, such as automatic nozzle alignment, automatic height measurement, dispensing weighing compensation, five-axis linkage and other functions, which can effectively overcome the difficulties of various dispensing processes and help improve Dispensing quality;

Supporting System

This stand-alone dispenser setup is suitable for 50ml, 400ml, or other packaged sizes of 2-part fluids, glues automatic dispensing purpose. Please feel free to send your MPP information; Material, Product, Production details and requirement to us, our engineers will provide free evaluation and solution.

CASE

Machine positioning:

One dispensing machine that can meet the application process of various industrial adhesive needs.

Technical insight:

Adopting platform standardization, function modularization design concept and technique, so that you can quickly install a dispenser that meets your mass production needs.