Introduction:

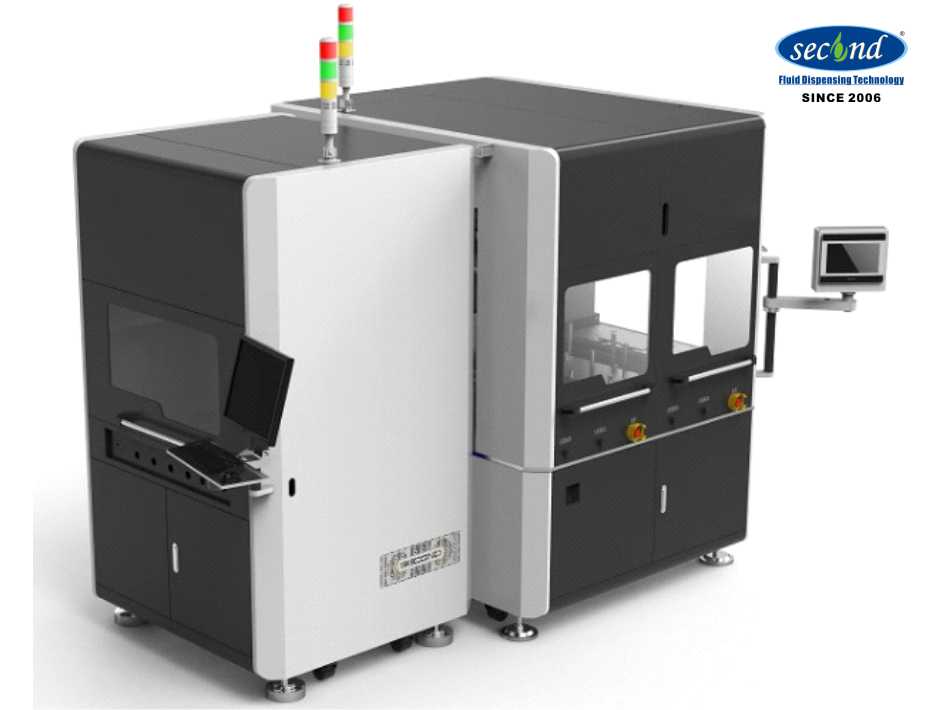

Hydrogen fuel cell battery is getting more important as an alternative power source for automotive vehicles, and also more and more stationary power supply are being developed. It is also a type of green energy, it has zero emission. Most of the machines and production lines we listed on this web-site have been built and sold to many clients already, and they have been proved success and reliable.

The company has begun to enter into the field of hydrogen fuel cell equipment in 2014. After years of researches and developments, combined the good experience in automated adhesives dispensing knowledge and the hydrogen fuel cell battery fabricating know-how, the company has successfully developed and sold various type of PEM FC bipolar plate automatic dispensing, sealing, and packaging machines as well as production lines. We also provide the membrane electrode assembling, packaging, machine, and production lines as well as automatic battery stacking machine, air tightness testing machine, testing and inspecting machines, fully automatic stack system, assembly production lines and other related equipment. We have established a subsidiary company name Suzhou Second Hydrogen Energy Technology Co., Ltd for this section of business, Shenzhen Second Intelligent Equipment Co. Ltd. is the mother-company. Please feel free to contact us, we provide free evaluation, proposal, and looking into long-term cooperation partnership to develop the businesses, and gives the Earth one more green energy option.

.jpg)