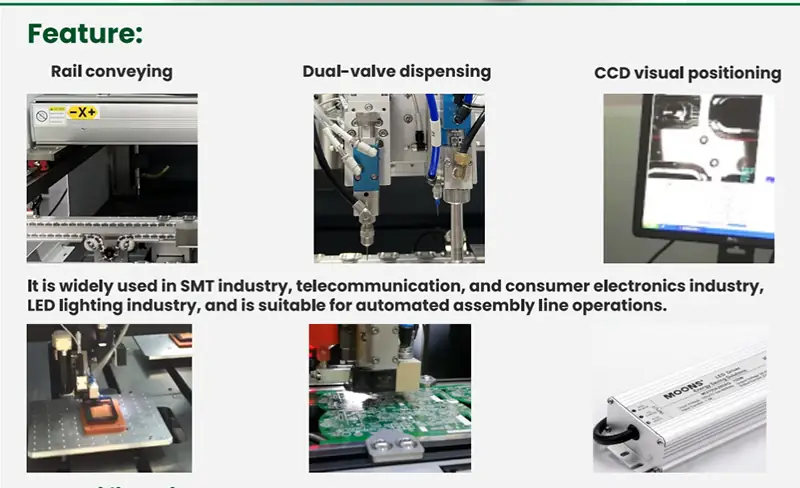

Features:

High stability –

The machine is built with good and durable structure. The integrated steel-frame, the travel system is applying with high precision servo-motor and lead-screw to make sure the dispensing and repeating accuracies with steady body and traveling system. The machine is using quality branding parts and components to make sure the robot, dispensing, and controlling systems are all steady and stable in long term to provide reliable and heavy-duty productions for years.

High volume production –

This model is especially design and build with dual-dispensing desks in order to meet with high capacity EMS production requirements. One operator can manage two dispensing systems.

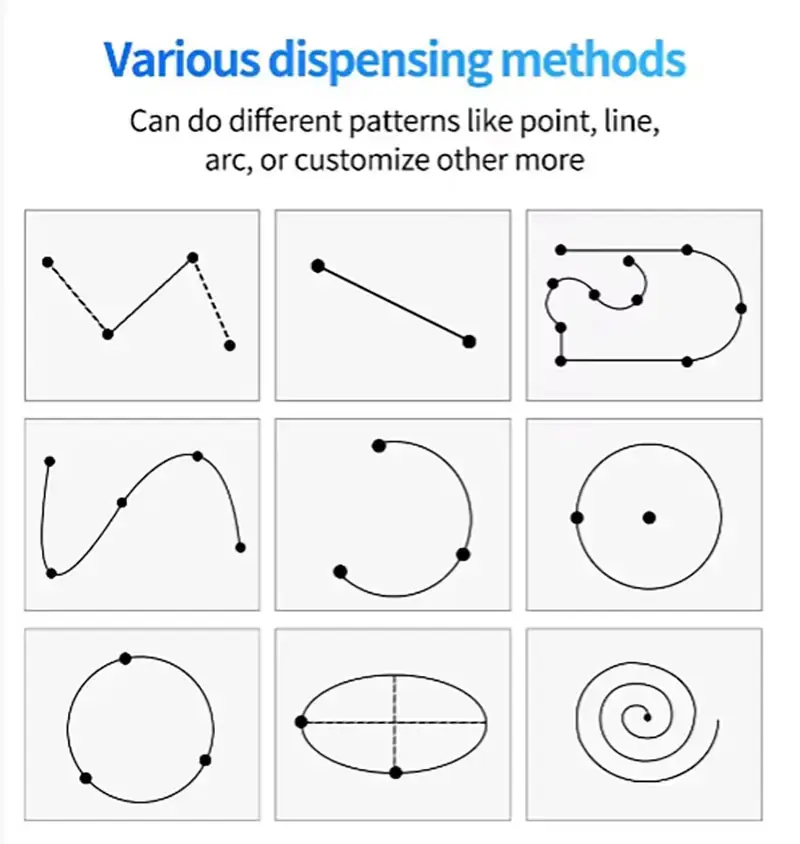

Dispensing process

Commonly used glue

Multi-valve picture display

Applications:

This SEC-5551B-2Y automated dispensing machine is used in UV packaging, hot melt adhesive bonding, epoxy bottom filling, underfill, and other similar material adhesive packages, and processes.

Dispensing Application