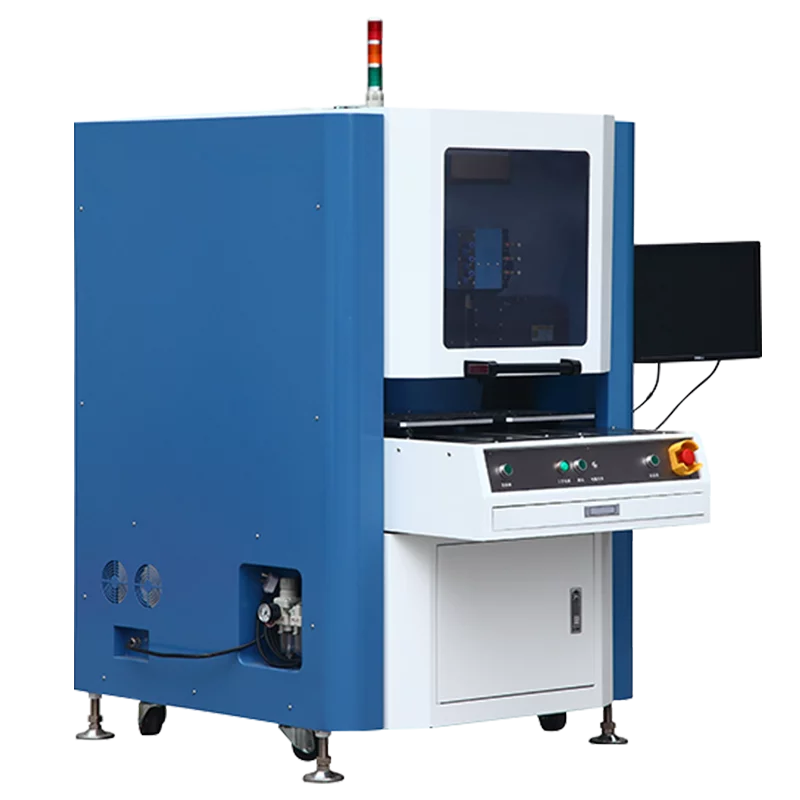

Machine:

SEC-DP200 machine is used frequently in silicone sealing, hot melt adhesive bonding, surface dispensing and mounting and other processes.

Material

It is able to dispense UV underfill, red bonding, solder paste, epoxy and other similar adhesives.

MANUFACTURING

This machine is suitable for UV dispensing, hot melt adhesive bonding, epoxy dispensing machine and other adhesive material apply processes. The machine comes with 2 sets of robotic system installed front and back of the machine. With this steup, in one machine, it can provide multiple functions, such as plasma treatment before dispensing; or UV curing after dispensing. It is suitable for high capacity UPH production, one operator can handle two stations efficiently and effectively.