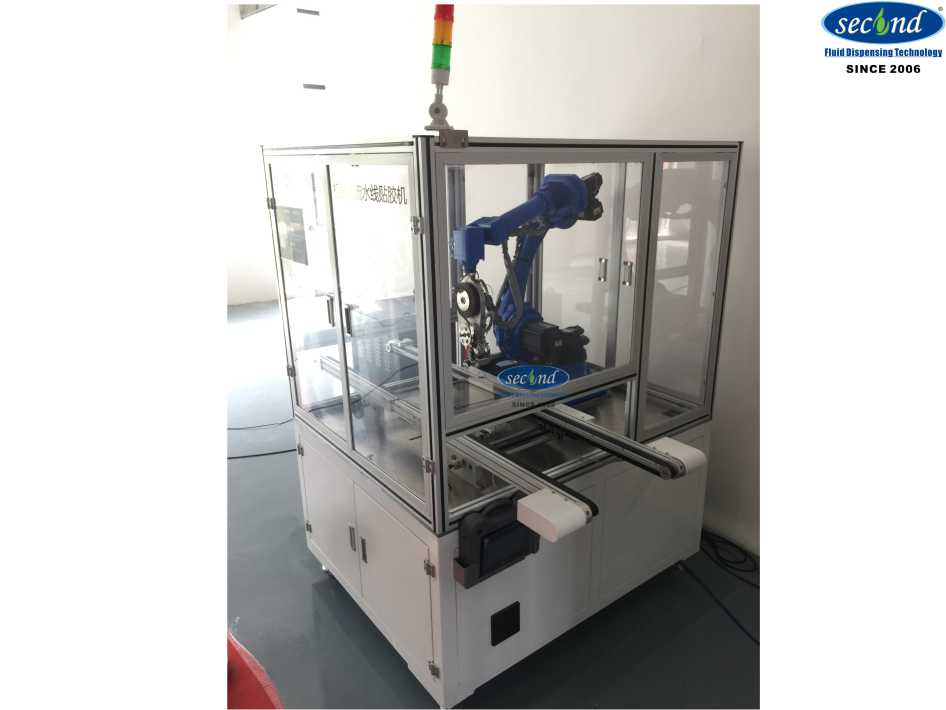

This is automated industrial adhesive material dispensing cobot works with a conveyor and equips with smart-visual camera that allows to automatic scan and dispensing SEC-NBR800CT-UL

Smart-visual dispensing cobot SEC-NBR800CT-UL

Description

Introduction:

This is a smart-visual dispensing cobot, it works with smart-visual system to scan incoming products and dispensing on the right spot(s), able to work with 1K adhesive or 2K adhesives.

Compare to traditional Cartesian dispensing robot, the XYZ axis still has its limit, our head office R. and D. engineering gathering together to design and build this series of new true dispensing robots.

With 6-axis robot arm, as the name describes, it has build in 6-axis already, so there’s no need to add additional rotating jig or fixture to rotate the product individually, and that gives more flexibility and wide expanded its production capability to meet and tackle different jobs, since it works more like human-hand.

The robots can adapt with various dispensing applicators to meet various adhesive materials and dispensing products needs. This design is suitable for dispensing most products. In the future, a factory can prepare several such dispensing robots for easy use at any time.

The working platform of the robot is an open design, with an automatic turntable or dual working stations. It can also be equipped with and integrate various dispensing applications and intelligent vision calibration functions. The robotic arm can also be changed to your own choice. We welcome your OEM logo and projects.

Features:

This is an automatic collaborative dispensing robot pairs with an inline dispensing conveyor.

This robot can scan detect the product to dispense.

The products can be lay in any angles, the robot is able to match and dispense with CCD visual camera.

The 6-axis robot can meet almost any 2D and 3D surfaces dispensing needs, the traditional gantry system machine cannot compare with it.

The system comes with automatic nozzle alignment to make sure the dispensing accuracy.

The robot teaching software allow to perform easy array, and different dispensing patterns to works like a human arm, and able to repeat accurately.

The smart control system can easy set dosing volume, glue speed, and dispensing trajectory to make sure stable dispense on each time.

The robot can be equipped with different dispensing applications and material filling systems, such as UV, hot melt, 300ml RTV, or two components mixing valve.

It can use different brands of 6-axis robot.

Robot is available in different sizes.

The system can add safety fence and light curtain sensors.

Benefits:

- Automatic scaning and dispensing, saving a lot of working time to line up the products.

- It has a wide range of uses and can use different dispensing systems to meet the application of different materials.

- It is flexible and can be used for dispensing different types of products.

- It is highly adaptable. It has 6 axes and can work like a human hand.

- It is smart, able to distribute on the surfaces and corners of almost all 2 dimensional and 3 dimensional products.

- The robot dispenser is design for low maintenance, flexible, and easy management.

Specification

Model | SEC-NBR800CT-UL |

Machine dimensions | L1000╳W1000╳H1350 |

Repeat accuracy | ±0.05mm |

Max payload | 5kg |

Air supply | 0.4-0.8Mpa |

Power supply | AC220V 50HZ 2.2KW |

Working environment | Humidity:20-90%, Temperature: 0-40℃ |

Machine weight | 200KG |

Machine made of | Industrial grade aluminum profile, sheet metal with powder coat. |

Transport system | Conveyor |

Travel speed | 0-500mm/s |

Working range (radius) | 0-800mm |

Operating system | Collaborative robot |

输送线系列(可选) | Belt conveyor line, chain conveyor line, front and rear connection lines, jacking positioning mechanism, side push positioning mechanism |

Visual auto positioning system (option) | CCD camera |

Additional functions(option) | CCD positioning function; automatic nozzle alignment function; automatic weighing function; automatic height measurement function; automatic cleaning function |

Dispensing systems(option) | 30CC syringe; 300ml cylinder ceramic valve; 300ml pneumatic cartridge + suck-back valve; 30CC + suck-back valve; 1.5 gallon + suck-back valve; 2600ml + suck-back valve; 30cc hot melt 30cc hot melt valve; external hot melt tank; two component automatic mixing dosing system; 5 gallon pump and dispensing valve; 55 gallon pump and dispensing valve. |

Supportive dispensing systems

Automated 6-axis cobot dispensers with smart-visual camera that allows to work with conveyor to scan and dispense.

MANUFACTURING

.jpg)

SOLUTION

Material

Two parts silicone, resin, epoxy, polyurethean and other fluids with big tanks or barrels of materials.

This machine is designed and built for the two components (2 parts) materials that need to be mixing together base on the ratio automatically. The machine equips with CNC automatic dispensing robot, which able to perform automatic dispensing efficiently and effectively without operator. The system comes with two tanks (15, 30, or 70 liters as the standard, option for custmization).

Control

1. The machine is user friendly, and operating by Window base software.

2.The software is design and developed by Second Intelligent.

3.With over 15 years in dispensing and potting, the software has included all of the functions that meets dispensing and potting needs. And it has been fine tuned and debugged well to provide good quality output.

4.The software has English instruction, and we welcome your language as well.

5.It is absolutely user friendly. With this computer system, it comes with an internet remote control access function, this allow us to help operator to conduct troubleshooting of the software, and can be used as an online instruction as well. It is welcomed, easy and helpful for international service and support.

FAQ

We are direct manufacturer.

Generally, we pack our goods with proper wooden box. However, if client has special requirment, we can customize.

Depends on terms and conditions, negotiable.

Yes, we can produce according to the tested result. We can also product base on your design.

Yes, we will test 100% before delivery.

We keep good quality and competitive price to ensure our customers benefit. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Dispensing machine is an automatic machine and equipment that specializes in controlling fluid and dripping, coating, and potting the liquid on the surface of the product or inside the product. The glue dispenser is mainly used for glue and paint in the product process.

Glue dispensers are generally suitable for small products or electronic components, which are more precise; the products of potting dispensers are generally larger.

As long as it is a fluid with a viscosity within a certain range, it can be operated. The glue generally used in the dispenser includes red glue, hot melt glue, silica gel, grease and so on.

A: Yes. Dual-fluid models with 1:0.8~1:1.2 mixing ratio control are available.

A: 0.1mm diameter with ultra-fine nozzles (requires low-viscosity fluids).

A: CE, UL, ISO 9001, and RoHS compliance for global markets.

A: Yes. Dual-fluid models with 1:0.8~1:1.2 mixing ratio control are available.

INQUIRY FORM